HSS circular saw; the lowest-cost alternative to the solid carbide blade

The ideal sawblade for small jobs

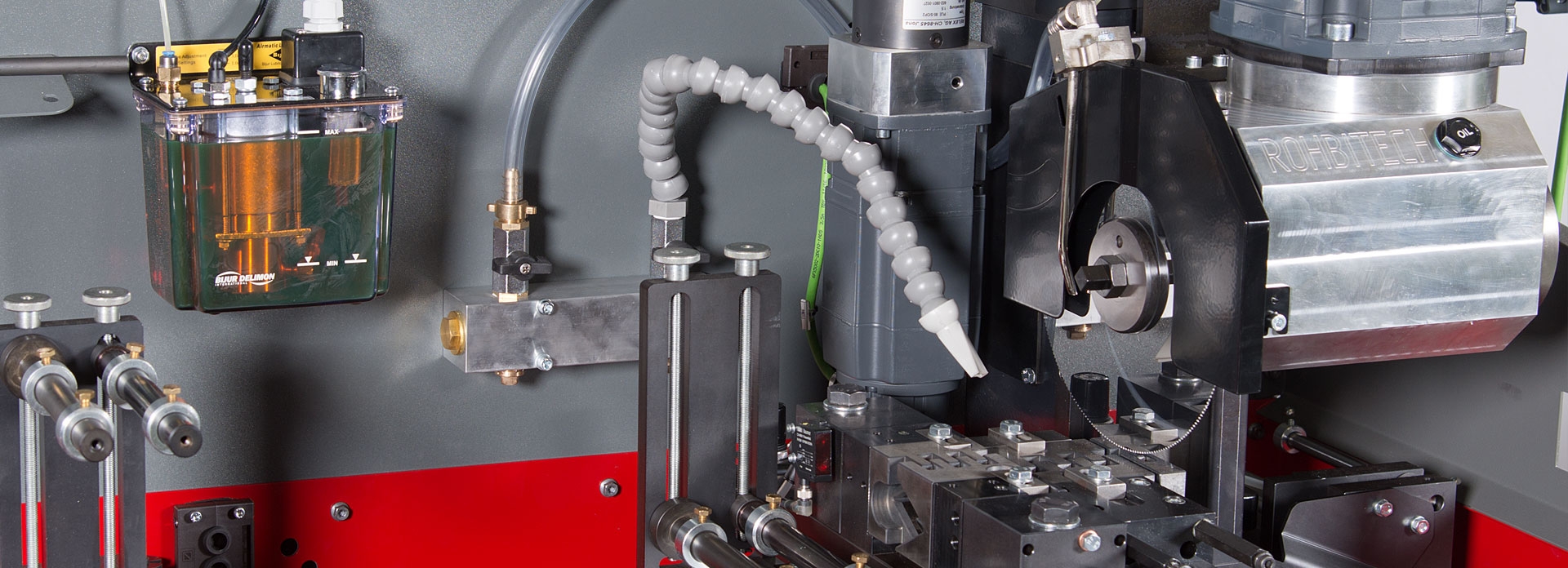

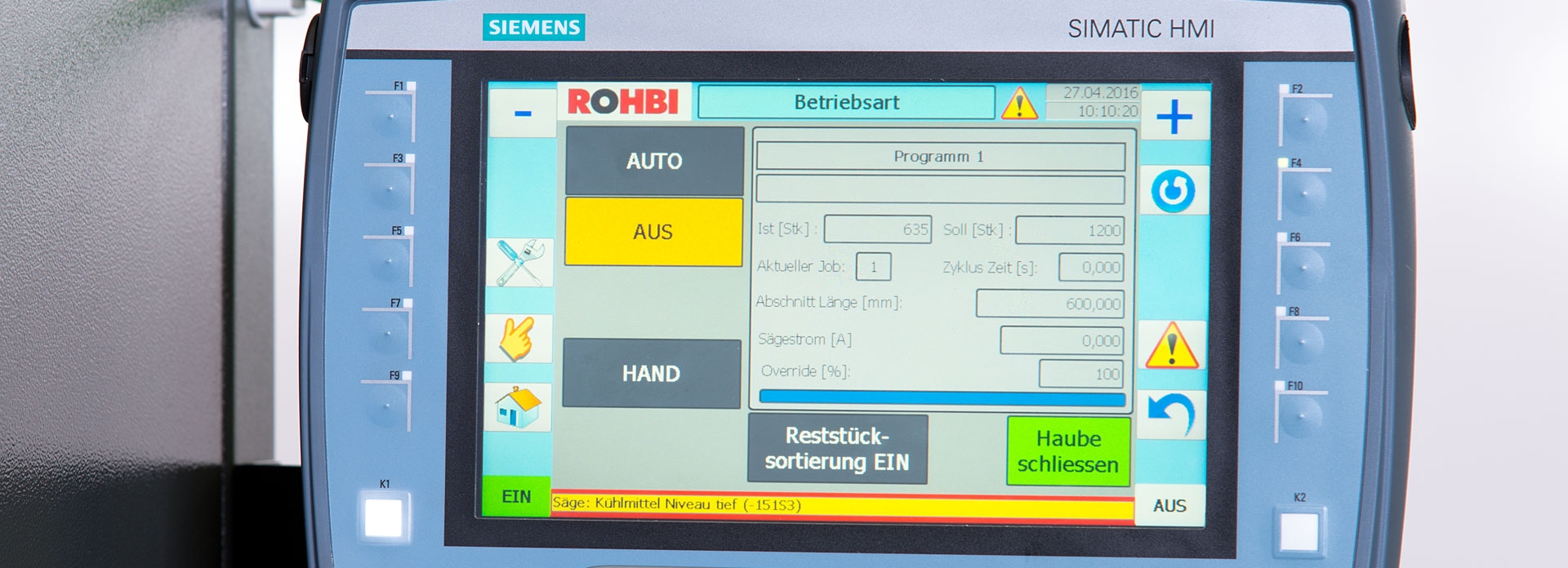

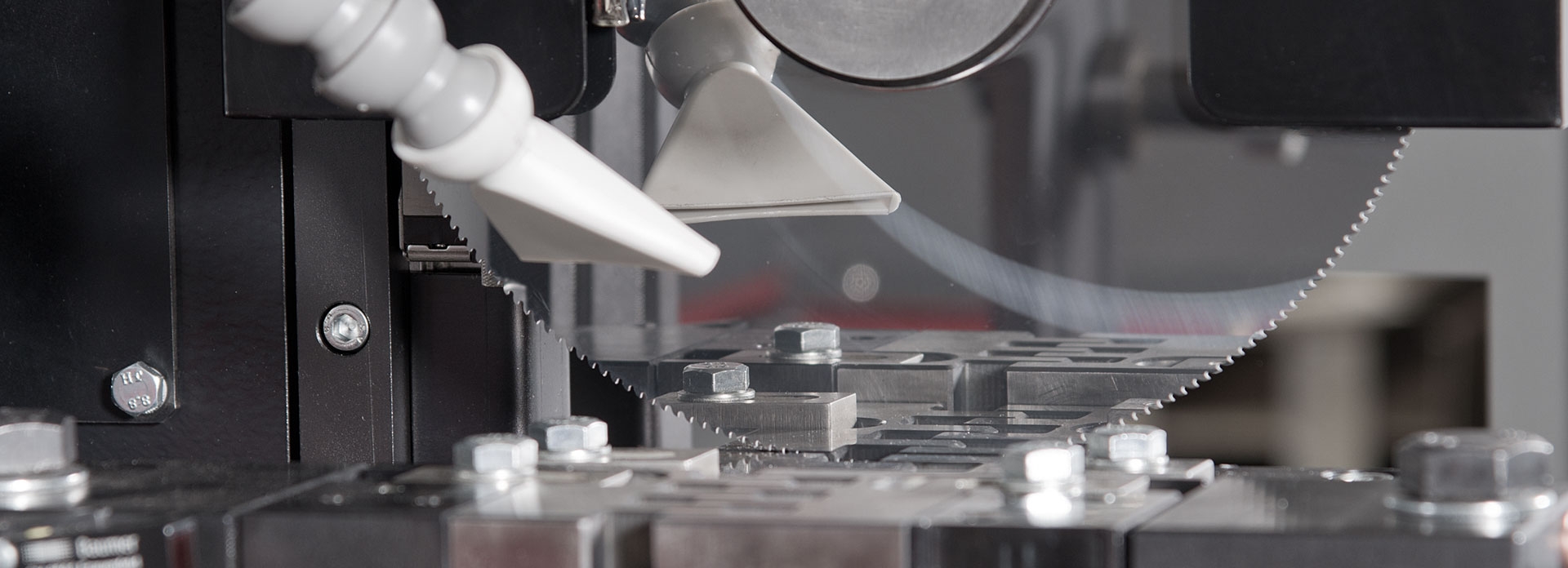

The HSS circular saw is the right choice if you produce small jobs in your operation. HSS stands for high-speed steel or high-performance fast steel. It can be nitrided, which increases endurance. As an alternative, carbide steel is sometimes coated with PVD. This heat treatment increases the overall endurance of the sawblade, thus sawing more parts. The benefit of this sawblade is particularly cost-savings, increased life compared to conventional steel, and ease of procurement.

Technical specifications for our HSS sawblades

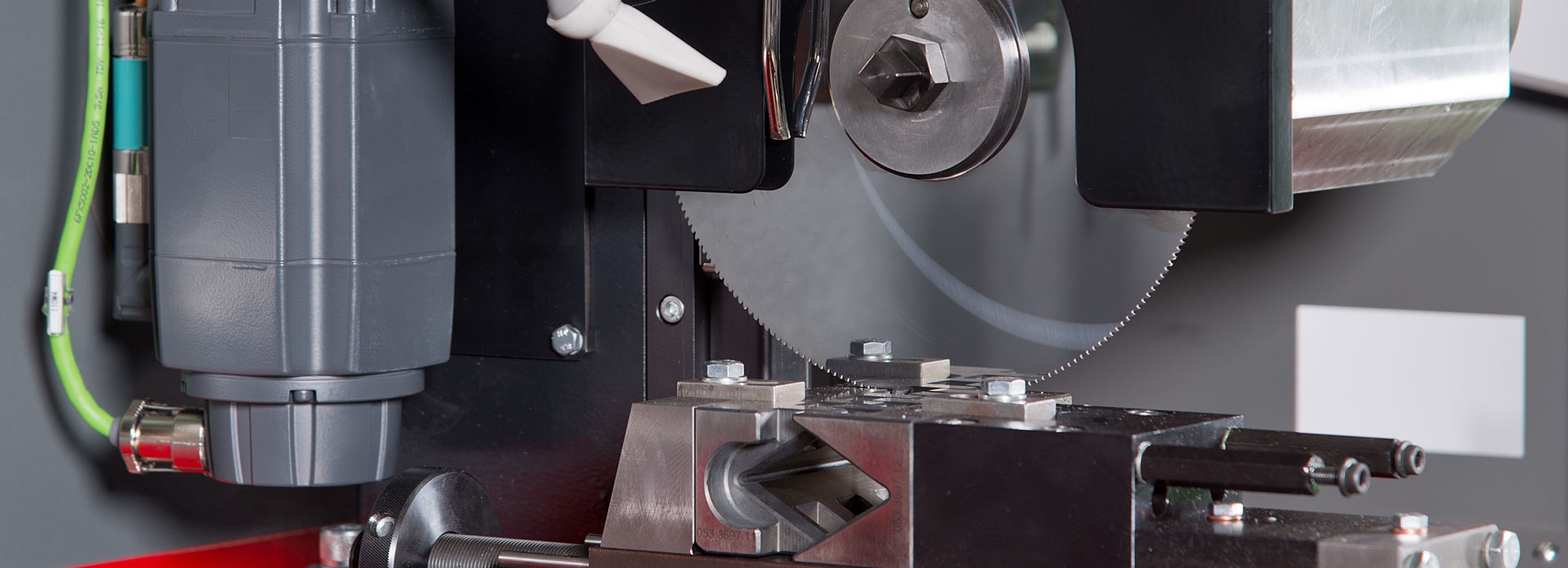

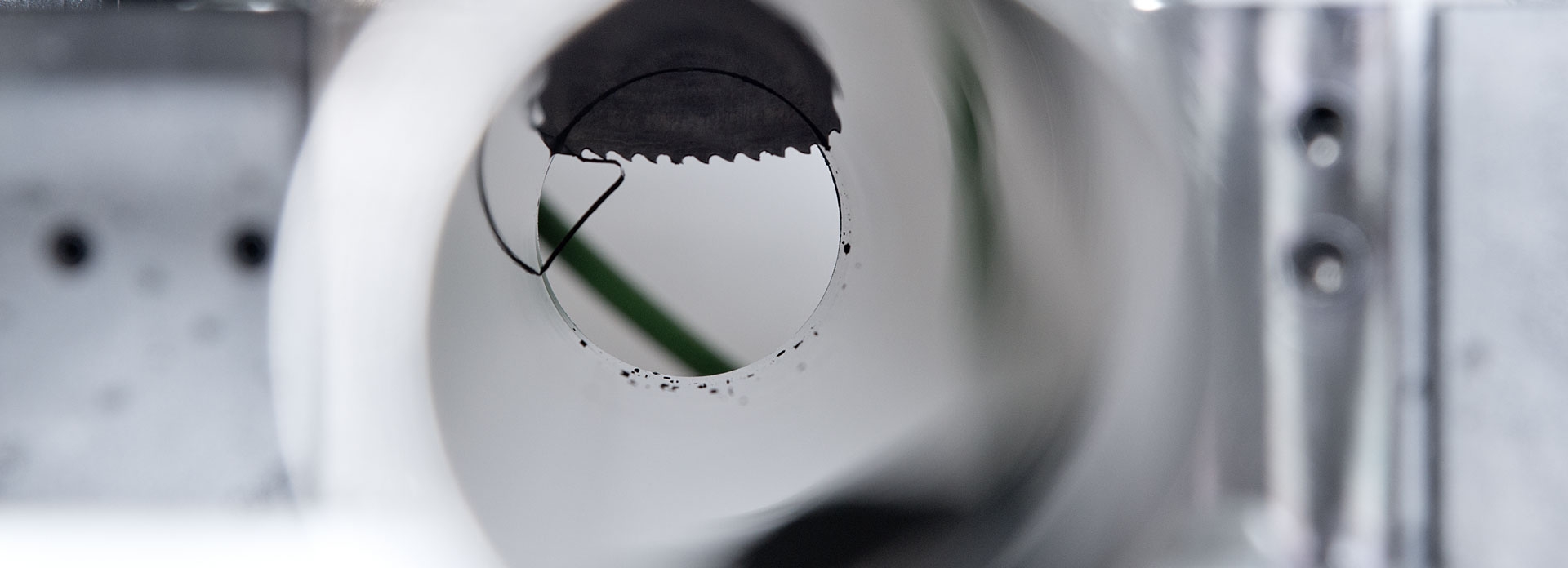

Our high-performance fast steel is high-alloy tool steel which is particularly suitable as a cutting material for saws, mill tools, chisels, drills and broaching tools. One can reach significantly higher cutting speeds with the HSS circular sawblade in comparison to normal tool steel. Alloy elements used include carbon, molybdenum, tungsten, chrome, vanadium and cobalt. Rohbimax AG offers the HSS circular sawblade in standard versions, which are relatively easy to buy on the market. Of course, you can also order larger diameter sawblades. Rohbimax offers blades with diameters between 100 and 250 mm, and thicknesses of 1 to 2.5 mm. There is of course more scrap when working on semi-finished products with an HSS sawblade as compared to a full carbide circular sawblade. Thus it is not appropriate to use on materials such as gold, silver or copper, where one wants to have the lowest-possible material losses.

Custom sawblades from Rohbimax

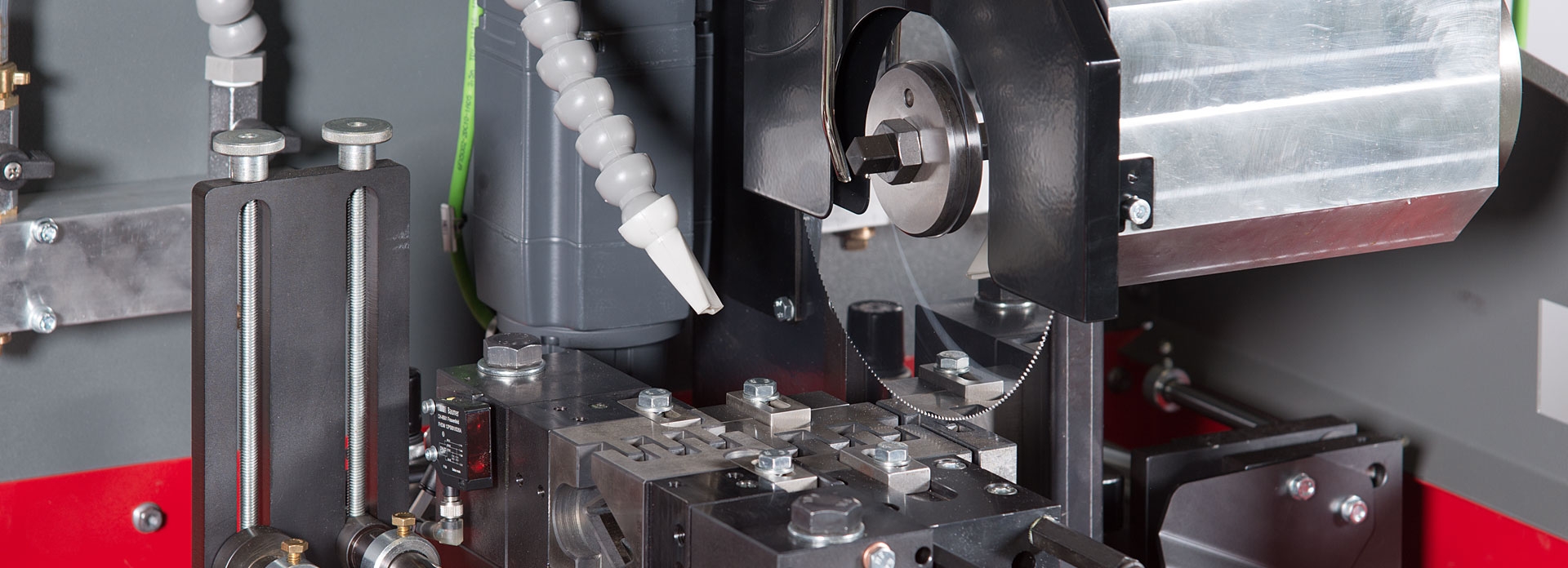

In addition to our standard models, we are also your contact when you need custom saw solutions. Come visit us at Schwarzenbach with your semi-finished products, or send us the exact dimensions of the workpiece. We would be happy to advise you on the execution of your sawblade in connection with your automated sawing machines or a machine from Rohbimax. Sawblade diameters up to 250 mm are optimal for use in Rohbimax machines.