Reduce cleaning efforts for sawing machines thanks to shavings removal

How to maintain a clean production environment

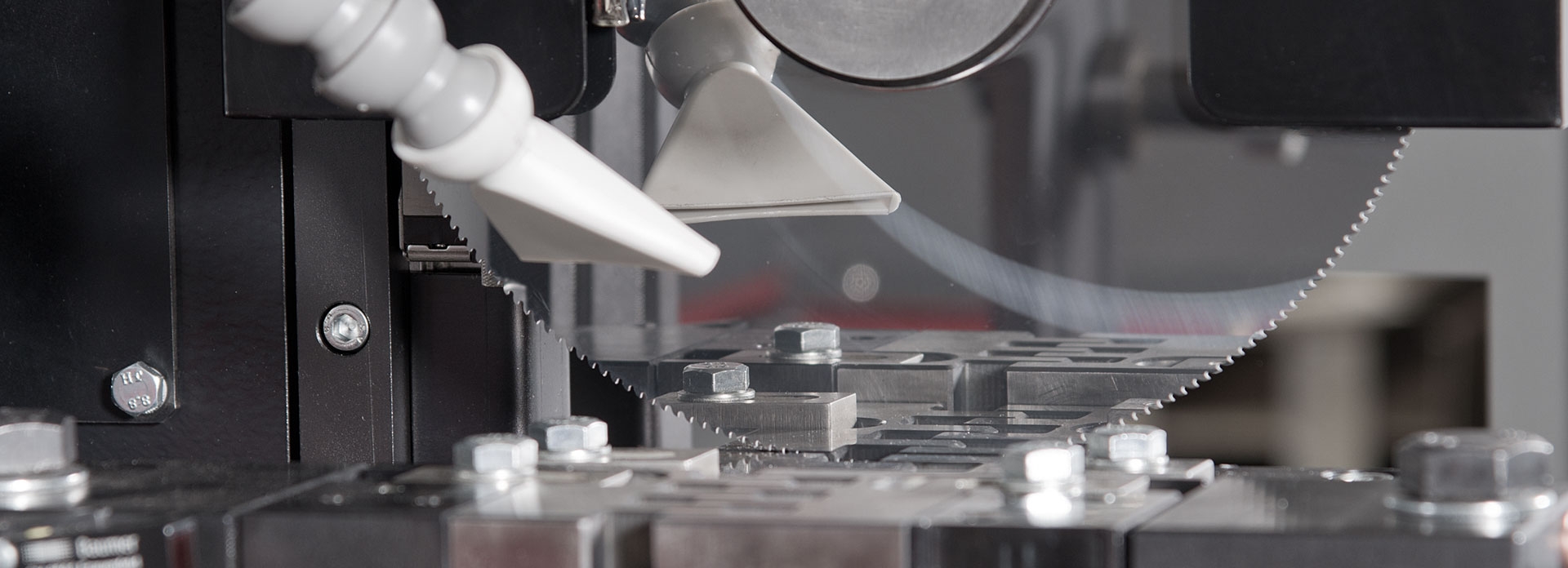

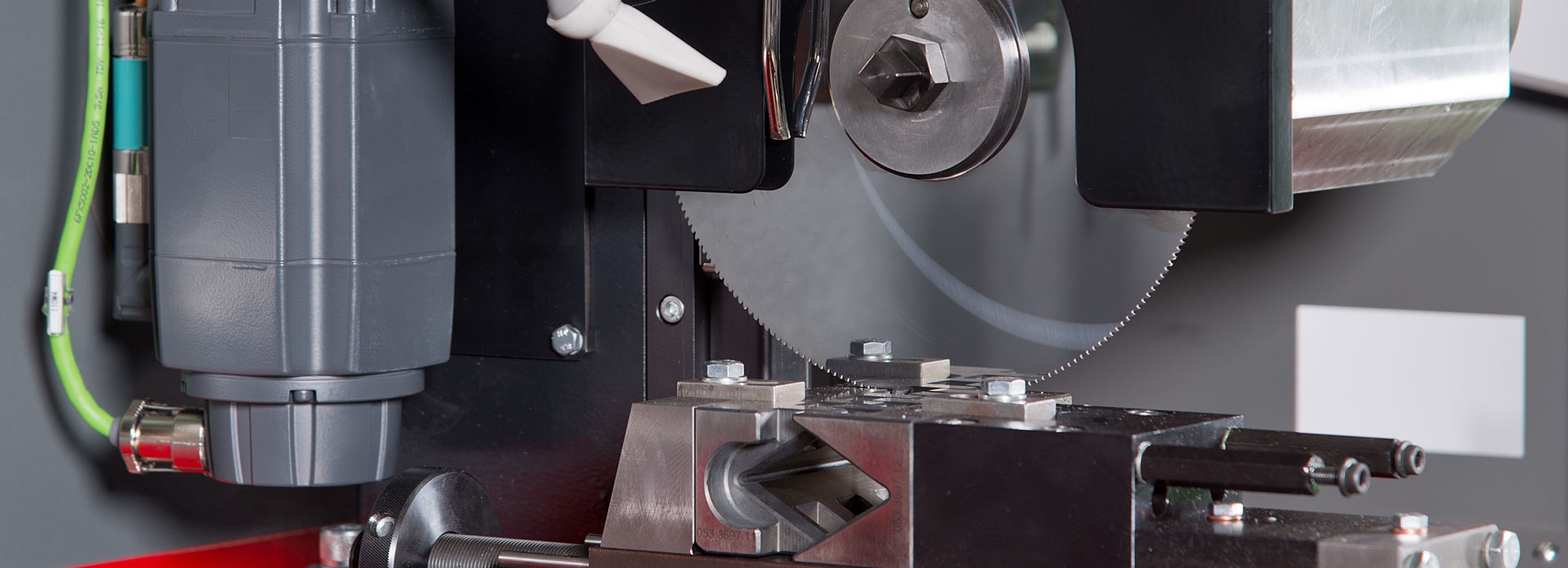

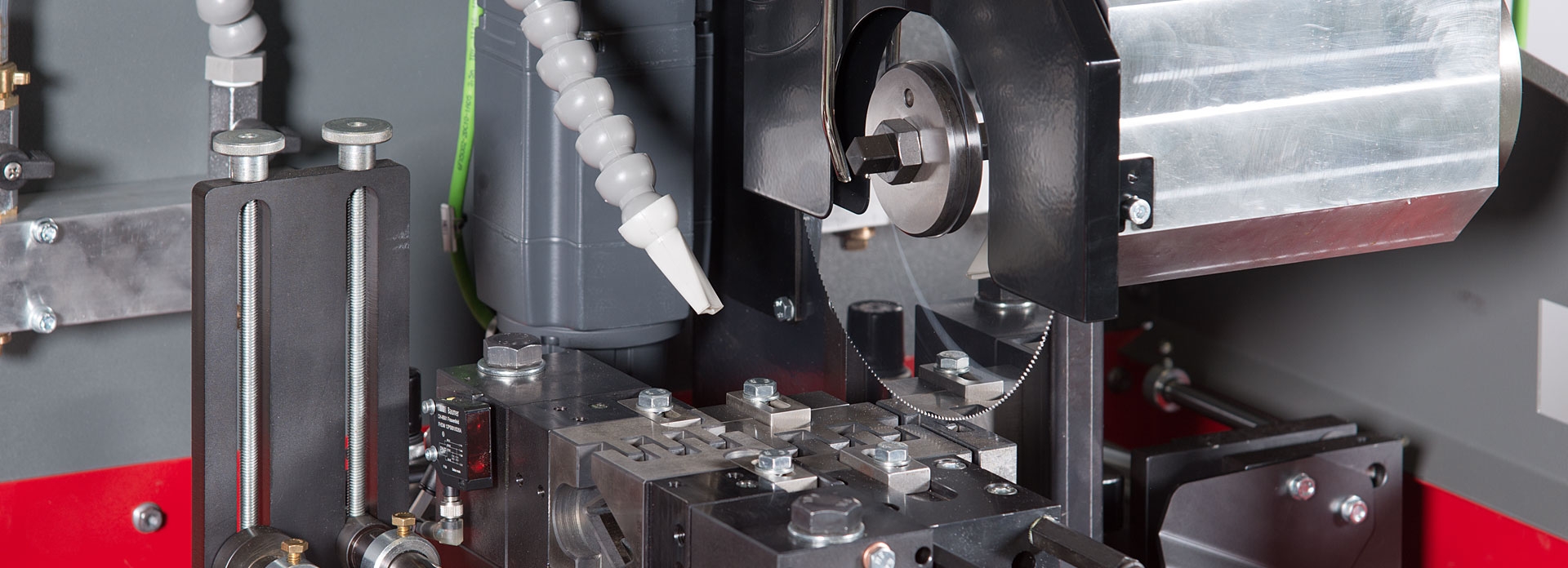

A lot of shavings are produced as a side-product when blanks are sawn from metal. It’s important to remove these shavings so that the machine does not become very contaminated. This significantly reduces maintenance efforts for your automated sawing machine, and the blanks are nearly shavings-free. Individual or central shavings removal is essential in production in which the systems run round the clock.

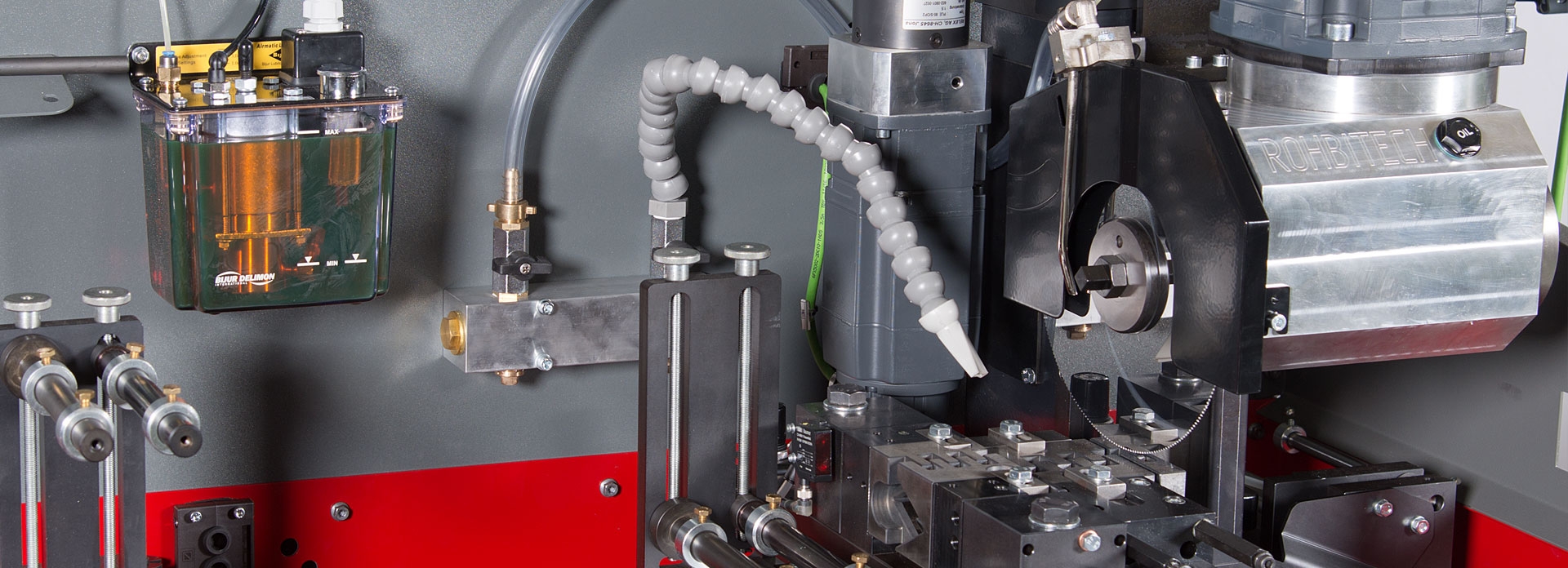

Shavings removal with minimal volume lubrication

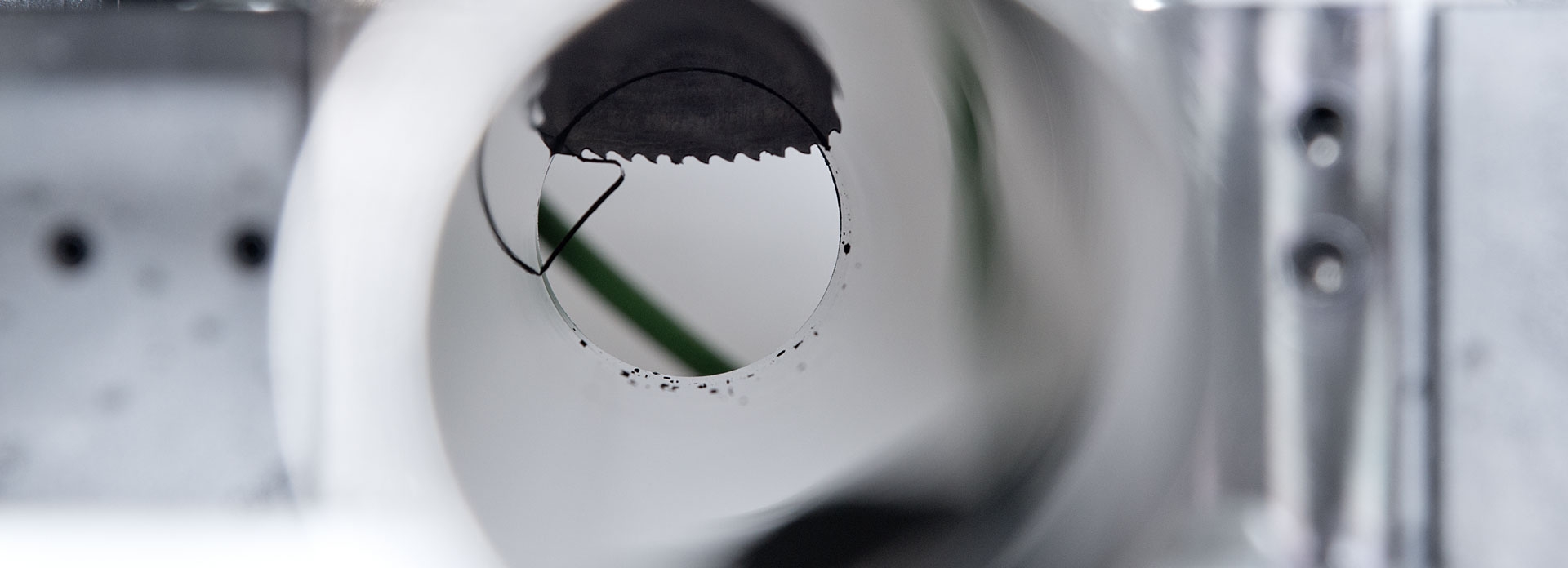

If a machine saws constantly, the sawblade must be cooled continuously and sufficiently, as well as lubricated and rinsed. One way to do this is with minimum volume lubrication. The advantage of this lubrication is that there are few oil remnants left on components. The disadvantage as compared to using coolant lubricant are the shavings that stick to saw teeth. Thus, shavings removal is highly recommended. This is usually directly connected to the machine so that the shavings are removed during the actual cuts. Thus, blanks need no longer be freed of shavings; they can go directly to the next processing step. When using cooling lubricant to cool automated sawing machines, shavings removal cannot be used. The cooling emulsion reliably rinses all shavings into the capture tank; but one cannot avoid having oil and water remnants on the components.

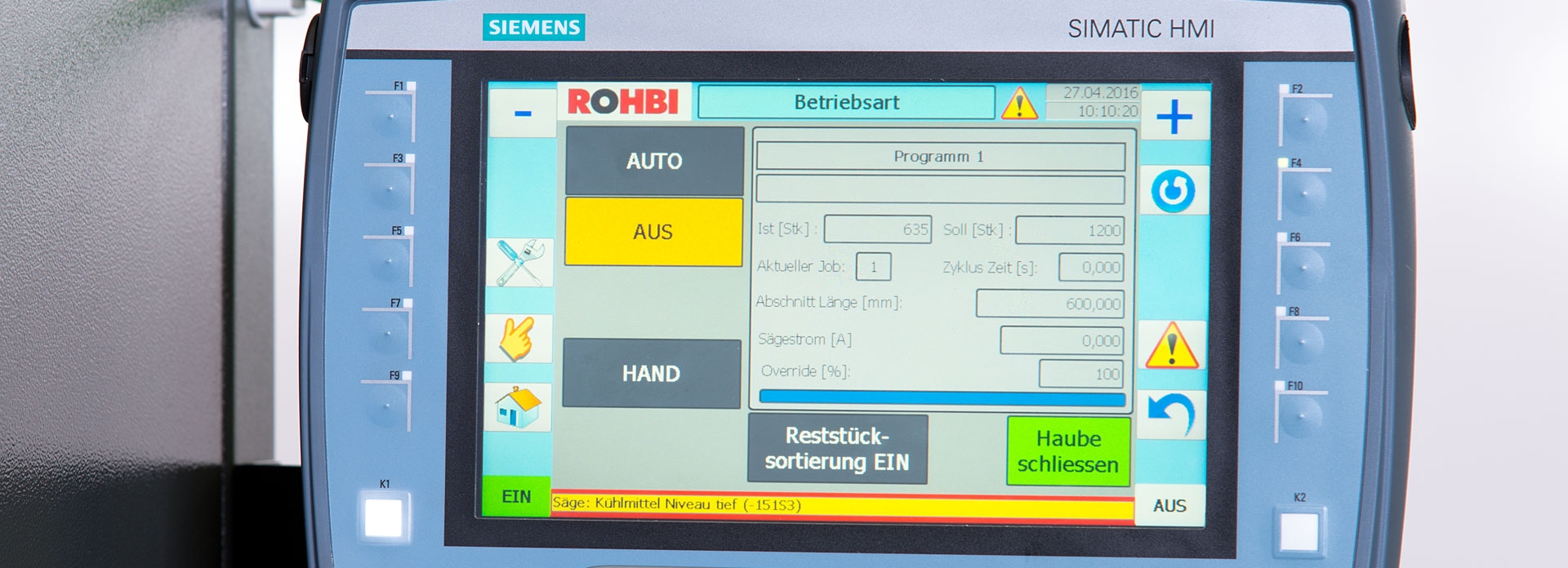

Rohbimax AG shaving removal

When using shaving removal, Rohbimax AG adheres to the highest safety standards, and tests to ensure that all parameters comply with CE standards. With shavings removal, you structure the production process to be cleaner, and reduce maintenance expense for your automated sawing machines. Since fewer shavings remain in the machine, the lifetime and useful life of the sawblades and cooling-lubrication are significantly increased. We would be pleased to consult with you on all options. Don’t hesitate to contact us.