Rohbimax AG – Top precision and high-performance production

Rohbimax AG brings more than 50 years of experience in precision sawing and is known world-wide for its innovative solutions. We create systems which are custom-made to meet our customers’ requirements. The quality solutions are ”Made in Switzerland”. Production increases and cost-savings are assured by our flexible, long-lived systems, precision to 0.02 mm and short cycle times.

Custom systems

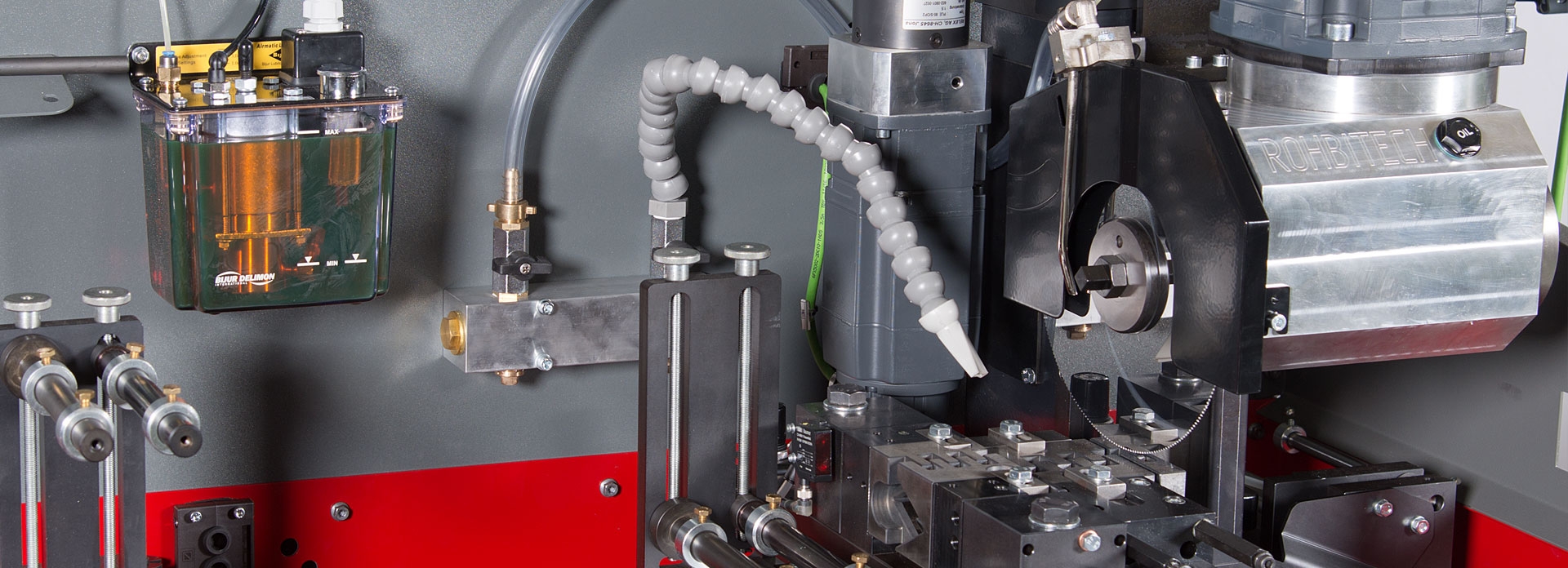

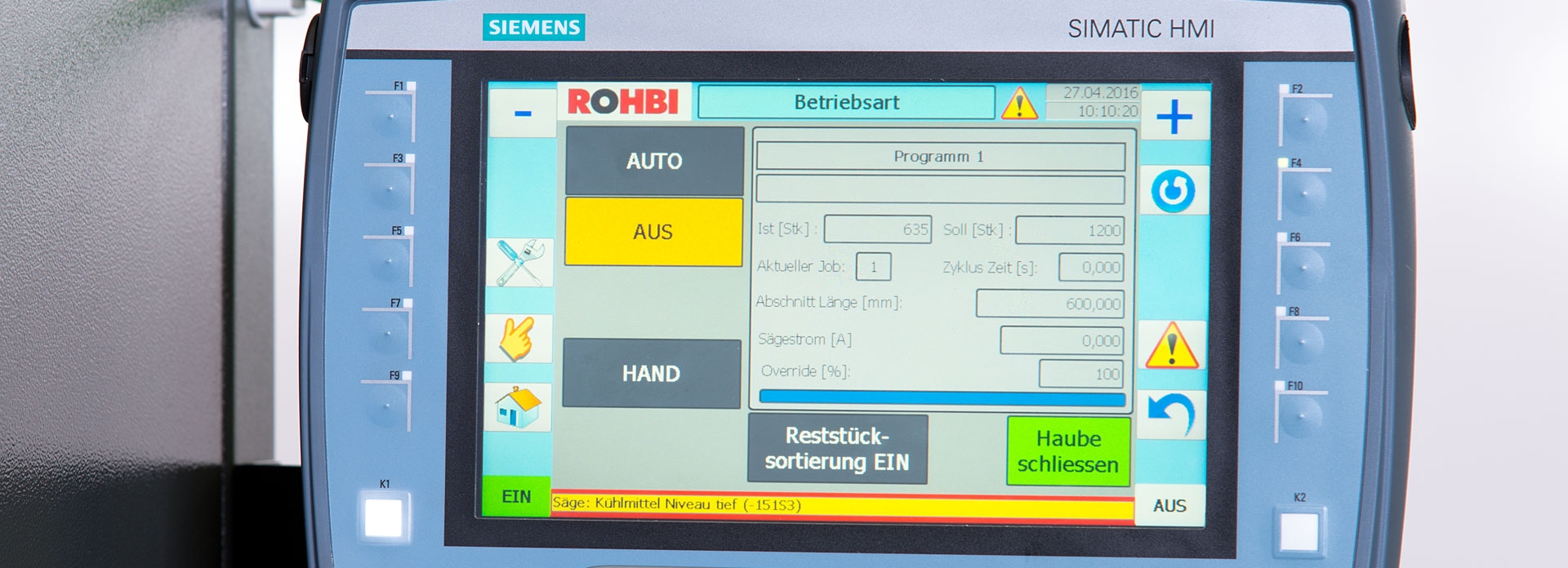

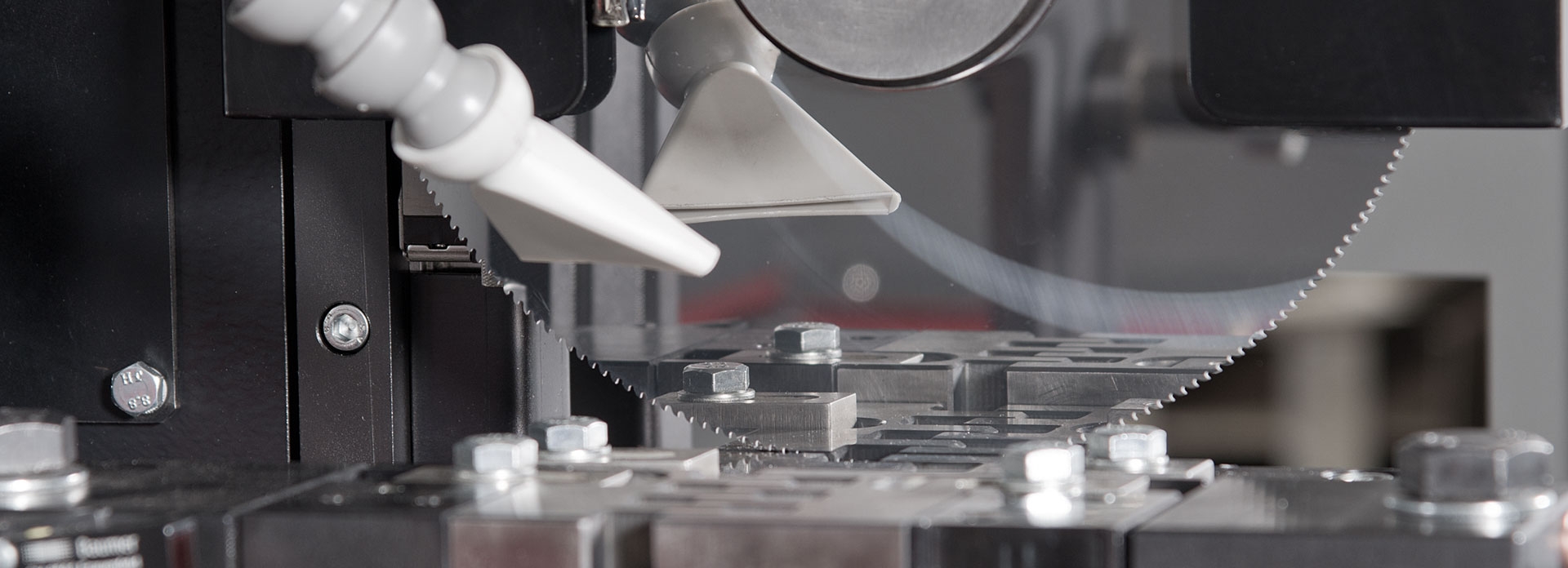

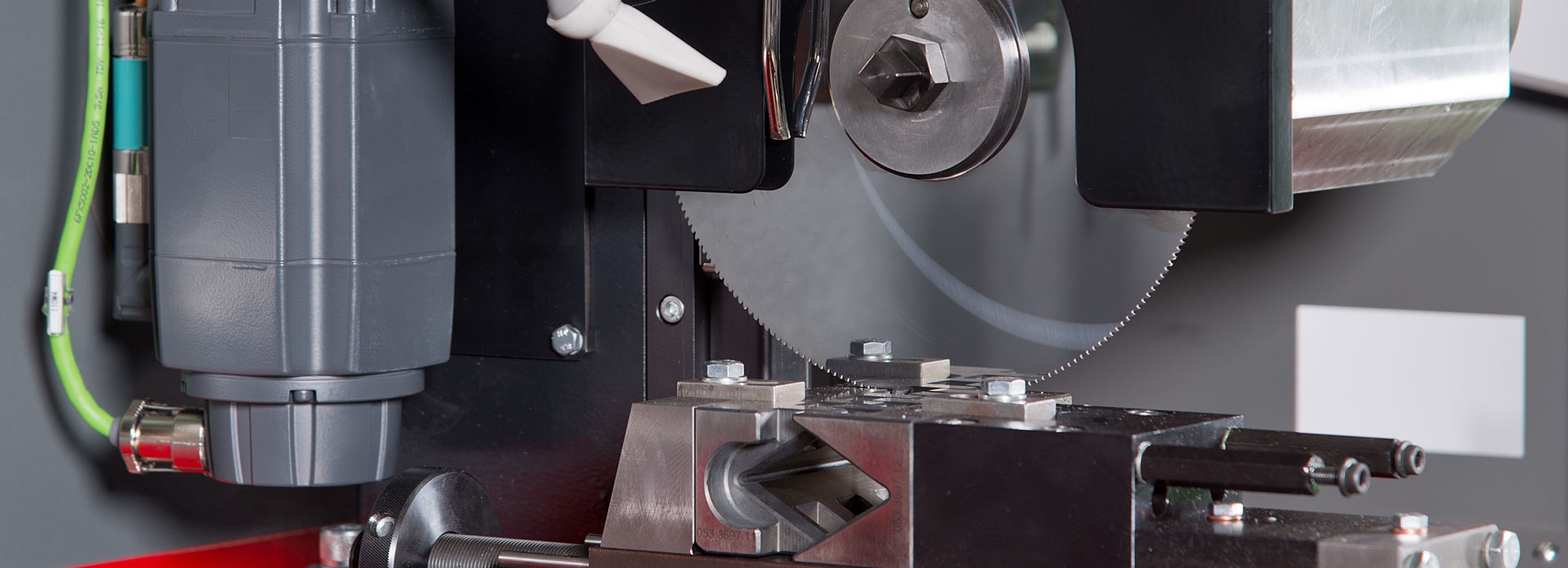

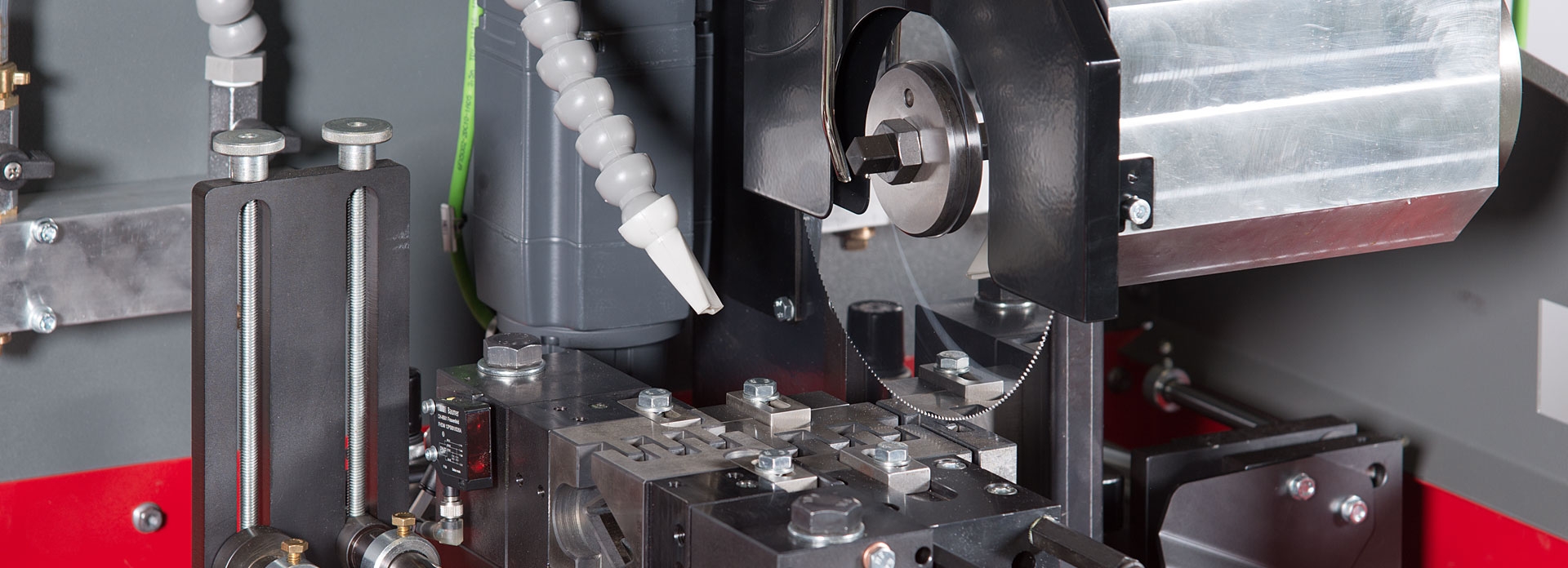

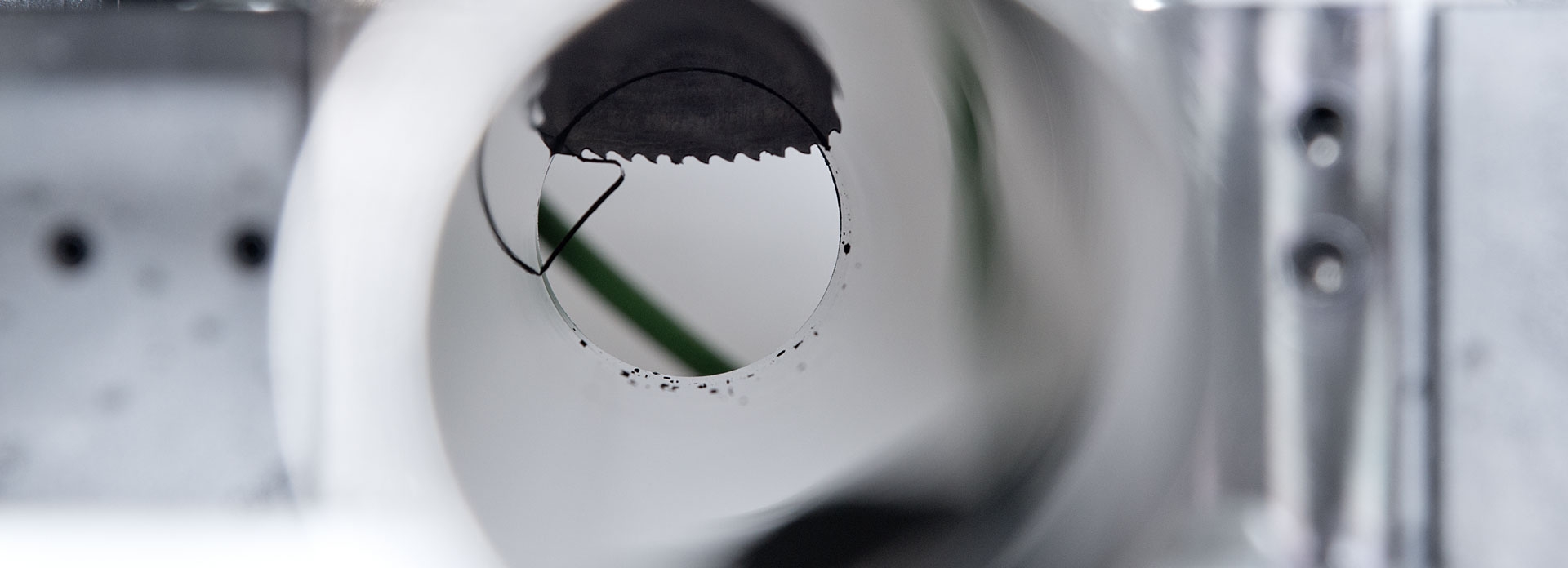

We find the best solution in collaboration with our customers, meeting their individual needs and requirements. All important criteria, including handling, the shape of the jaws, lighting and colours are included in planning. This ensures that our customers are satisfied long-term with our equipment. Depending upon the material to be processed and the dimensions, we provide saws with gears or high-speed spindles, with flowing or minimum quantity lubrication. They work quickly and easily on all usual metals and other materials. The exact fit of the jaws and prudent choice of sawblades obtain the best sawing results. The results are the smallest tolerances and as little material loss as possible, combined with high productivity. At the same time, parts sawed with Rohbimax machines can, in most cases, be used without additional processing. We also provide a large selection of peripheral instruments for feeding the starting materials and discharging sawn parts as part of an extensive automation process. Fully automatic feed and cuts to the desired size and for the needed number of pieces provide complete autonomous operation of the entire system. The teach-in process captures the height of the rods to the circular sawblade and can be programmed for five different speeds per saw cut.

Clear benefits of Rohbimax machines at a glance

- Parts sawn with great precision

- A variety of shapes, dimensions and materials

- Easy-to-operate system

- High productivity in an efficient production process

- Extensive service offerings

Rohbimax AG service

Individual system components are produced on modern metal-working machines and assembled under one roof in close collaboration between Rohbimax AG and Beni Burtscher AG. This enables us to implement customers’ requests with short supply times.

After purchase, we assemble machines at the customer site, inspect them together with the customer to ensure that they meet requirements, commission them, and train staff. After this, production can begin.

Thanks to the installed remote maintenance modules, our service technicians can upload software updates to the system, troubleshoot and even fix them remotely in some cases. We deliver spare parts when needed from our warehouse by courier to ensure that production can continue without interruption. We are happy to answer our customers’ queries.

Where are our saws used?

Rohbimax saws are used widely wherever precise cutting is needed on components at the beginning of each production process:

- Construction

- Machine tools

- Vehicle and aircraft construction

- Electrical devices

- Medical devices

- Office

- Household

- Jewellery

- Animal identification

Well-known manufacturers including Bosch, Siemens, Hydro Aluminium and many more belong to our group of satisfied customers.

”If you need to saw, choose Rohbi.”

Are you interested in Rohbimax AG’s precision saws? We would be glad to consult with you and provide additional information. We look forward to talking with you.