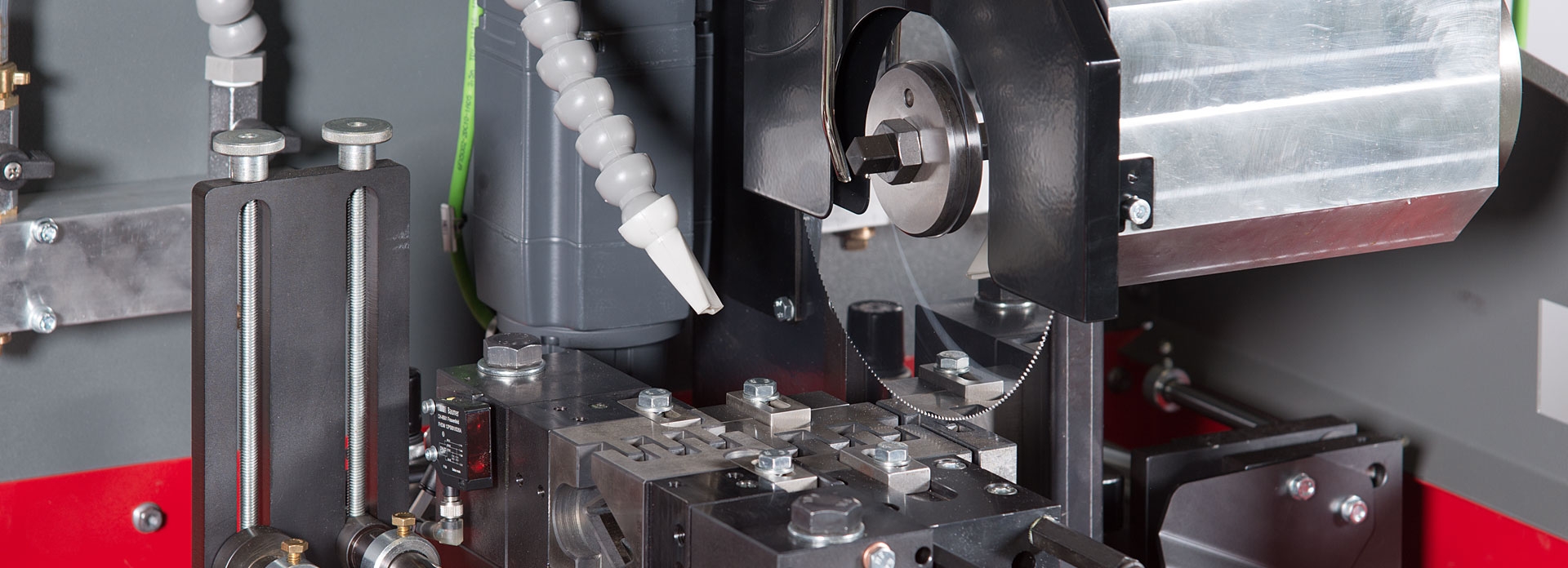

Automatic material feed using our bar feeder

Rationalise your work processes with a bar feeder

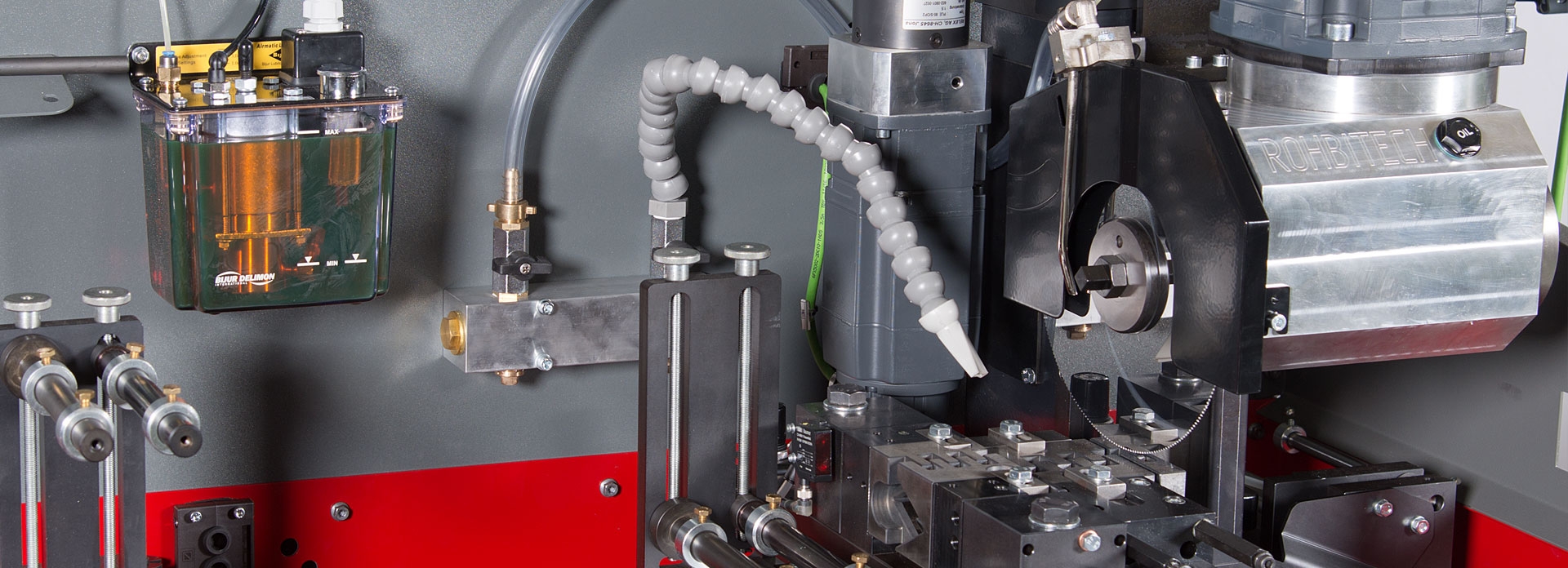

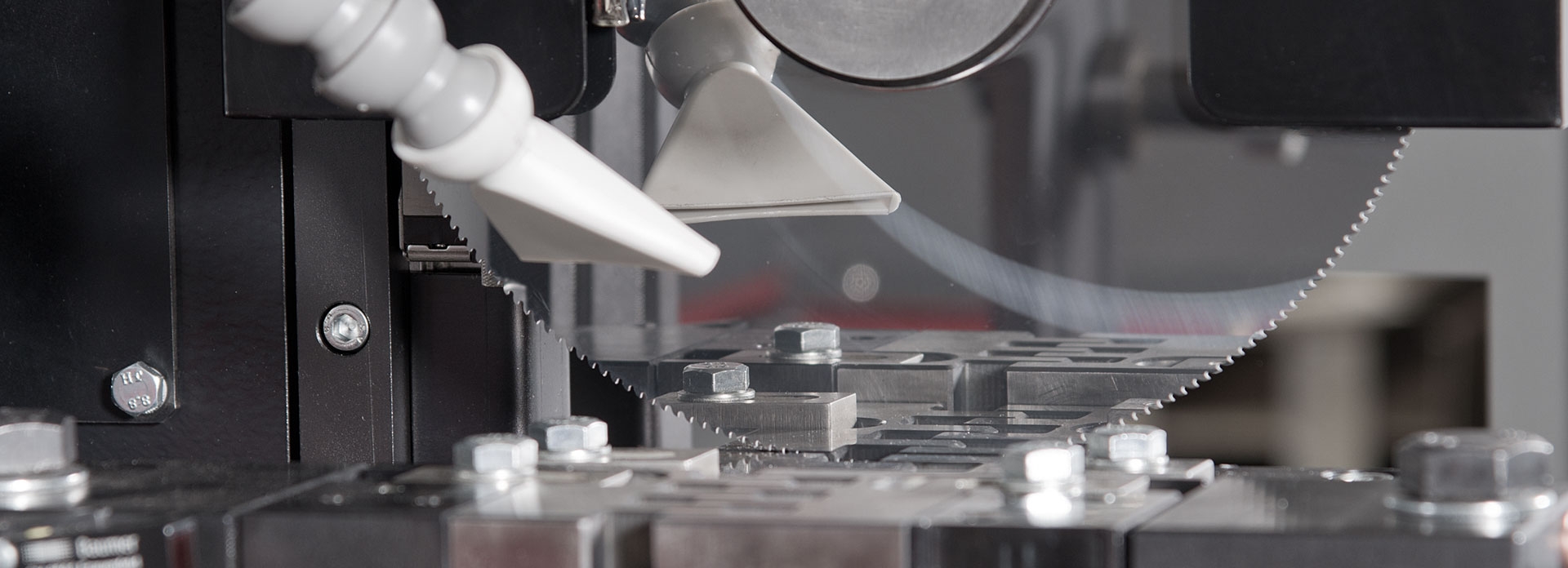

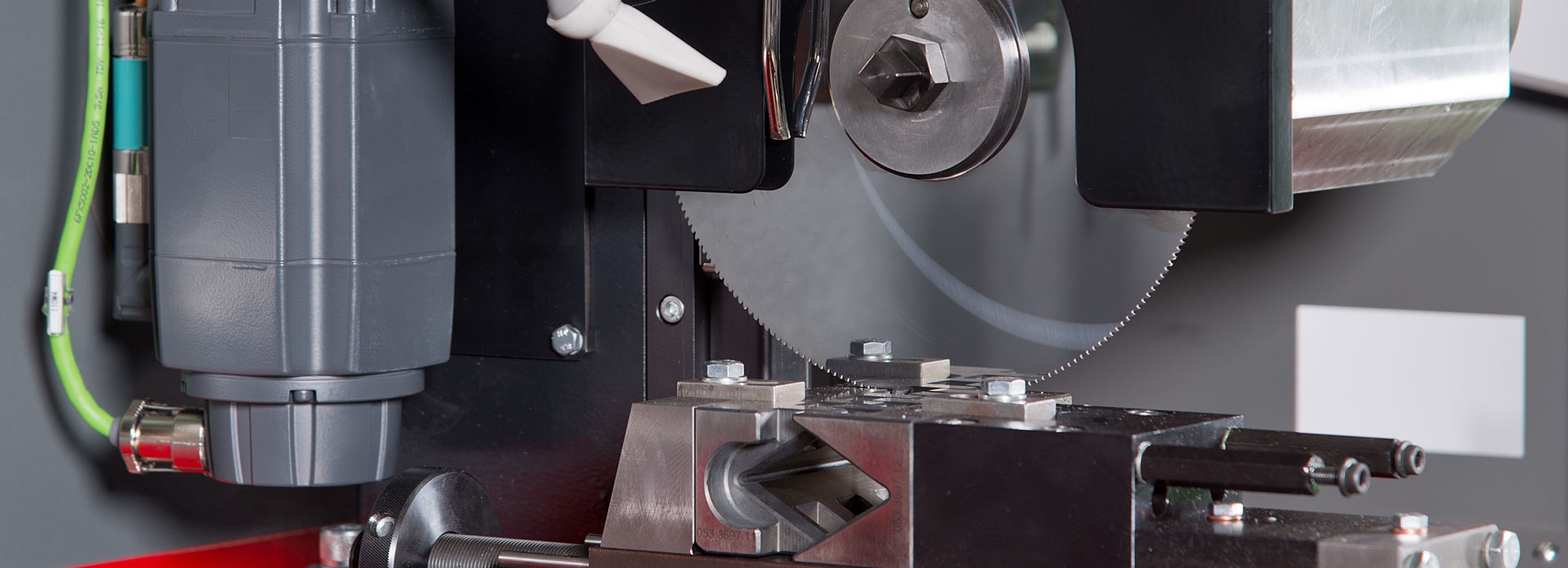

The bar feeder is one of the most important components to automate our sawing machines. This automatically feeds material to be sawn; the system can run between three and six hours on its own. One can feed either individual pipes or a bundle of pipes using prism jaws with the bar feeder. Additional feed is needed only after a few hours, and an employee can then manually load new rods.

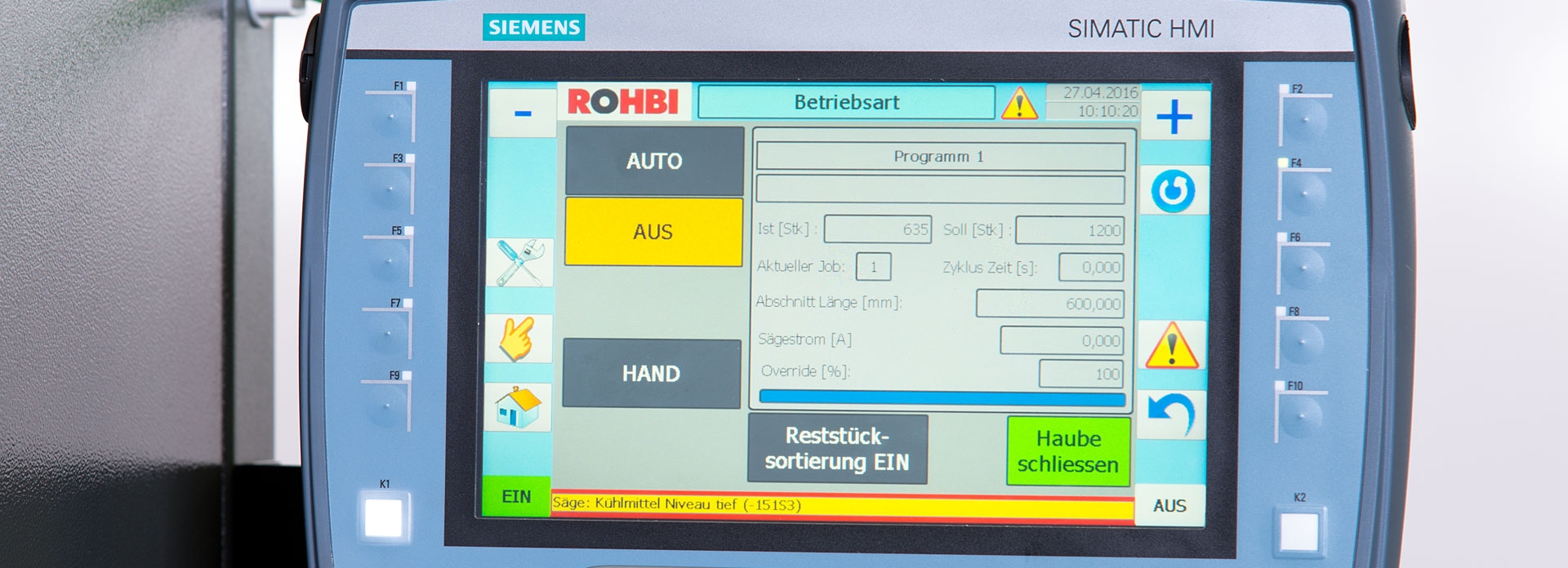

Various types of bar feeders

Rohbimax AG offers four different types of bar feeders: horizontal chain-driven magazines, vertical chain-driven magazines, a belt loader with transverse transport and a lift loader for individual small pipes and rods from a bundle.

| LA 172 horizontal chain magazine |

Loading width: 1700 or 1300 mm |

| LA 178 S vertical chain magazine |

Possible sizes: Ø 50 mm 10 / Ø 30 mm 15 |

| GX 174 belt loader |

Round materials: Ø 14 to 60 mm |

| HL 175 lift loader |

Round materials: Ø 6 to 30 mm |

Benefits of bar feeders at a glance

- A bar feeder helps you to rationalise the work process for sawing pipes, profiles, etc. Employees need only fill the magazine every few hours, as this automatically processes the rods one by one for the sawing machine Thus, you can save time and place staff at productive places.

- Fewer staff means fewer costs, also a benefit.

- Depending upon the industry, the rods to be processed are very large, clumsy and heavy. An automatic bar feeder makes the work much easier, as the rods need only be laid in the magazine.

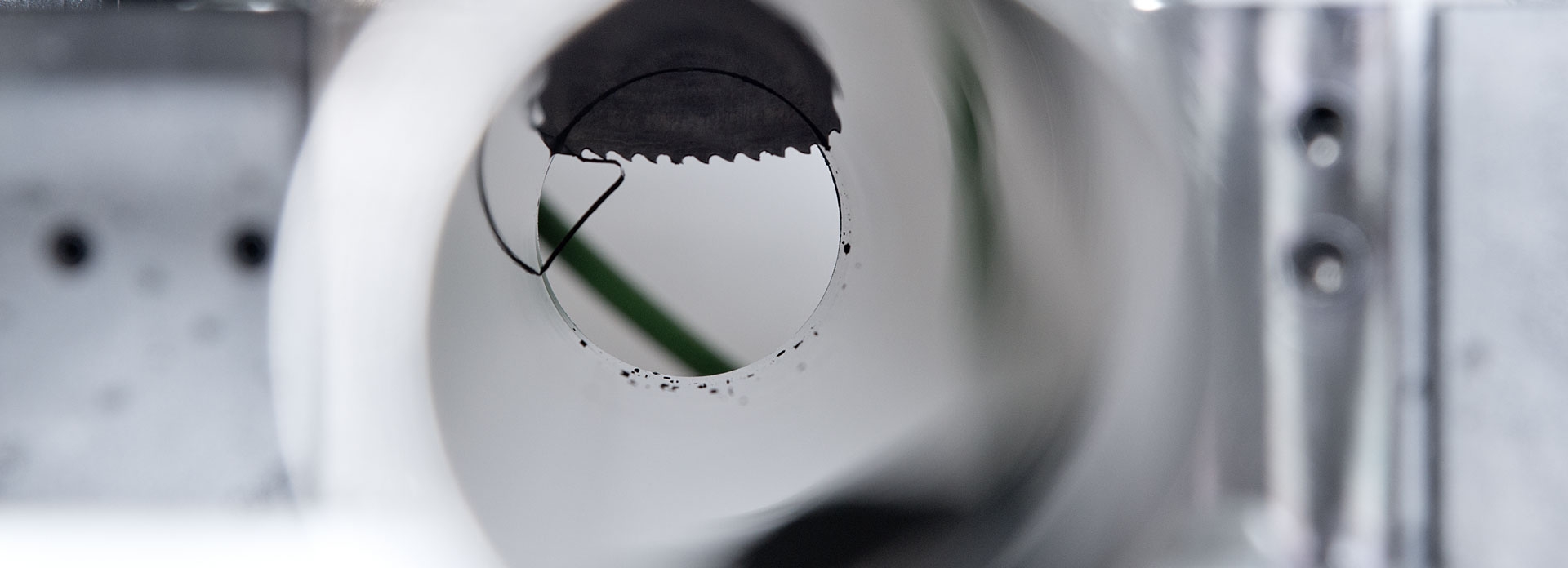

- Automatic pipe cutting can achieve much better results than manual work. The cycles are faster, and precision remains at the same high quality from the first to the last workpiece.