Precision circular saw for the best results: our RKA models

Precisely saw solid metal, profiles and tubes

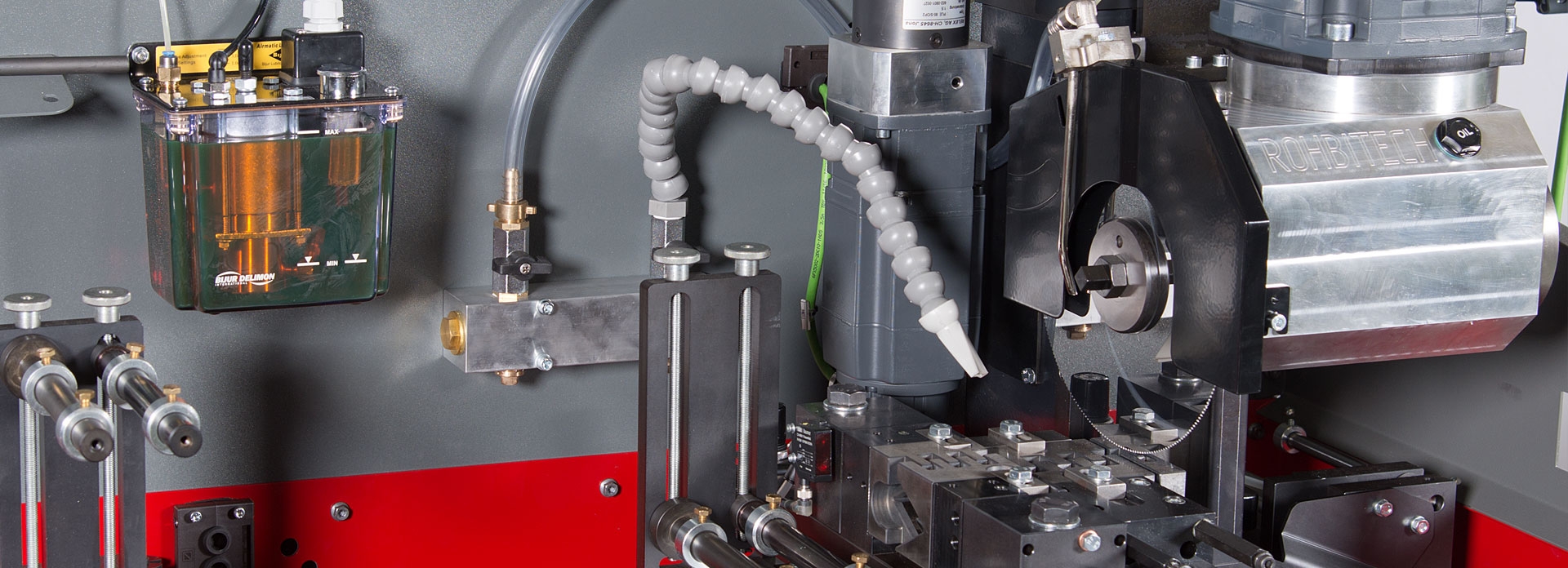

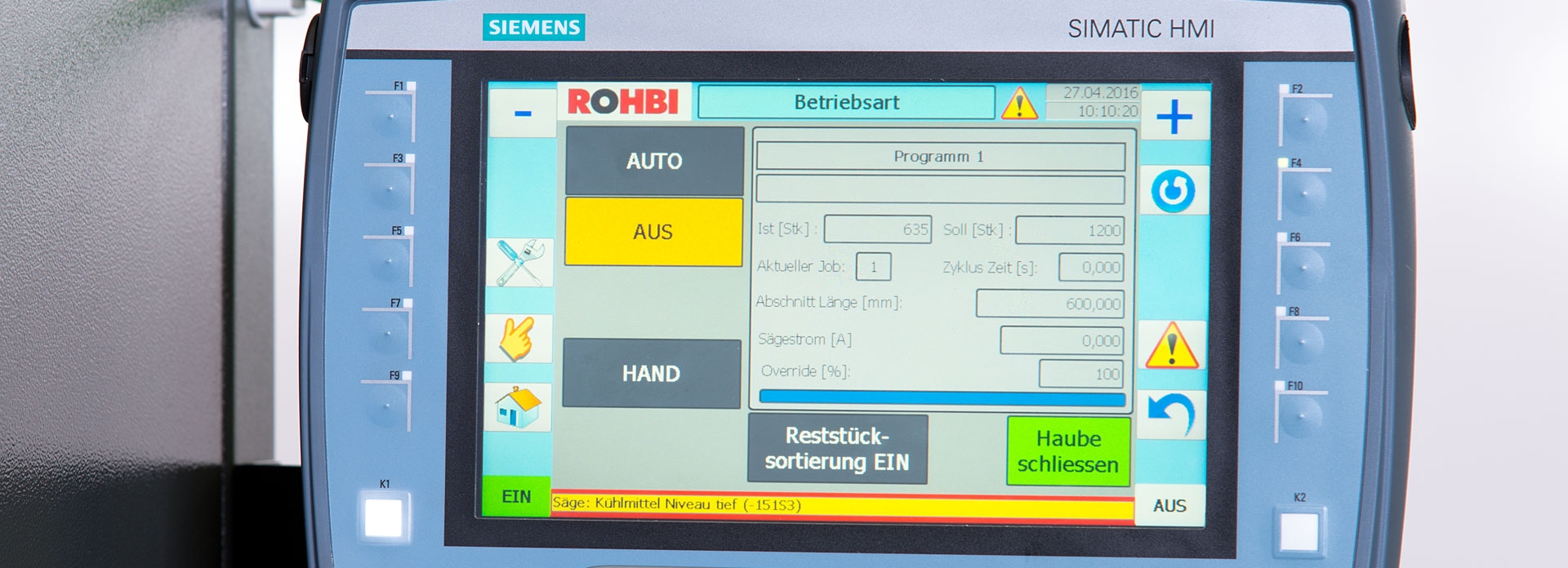

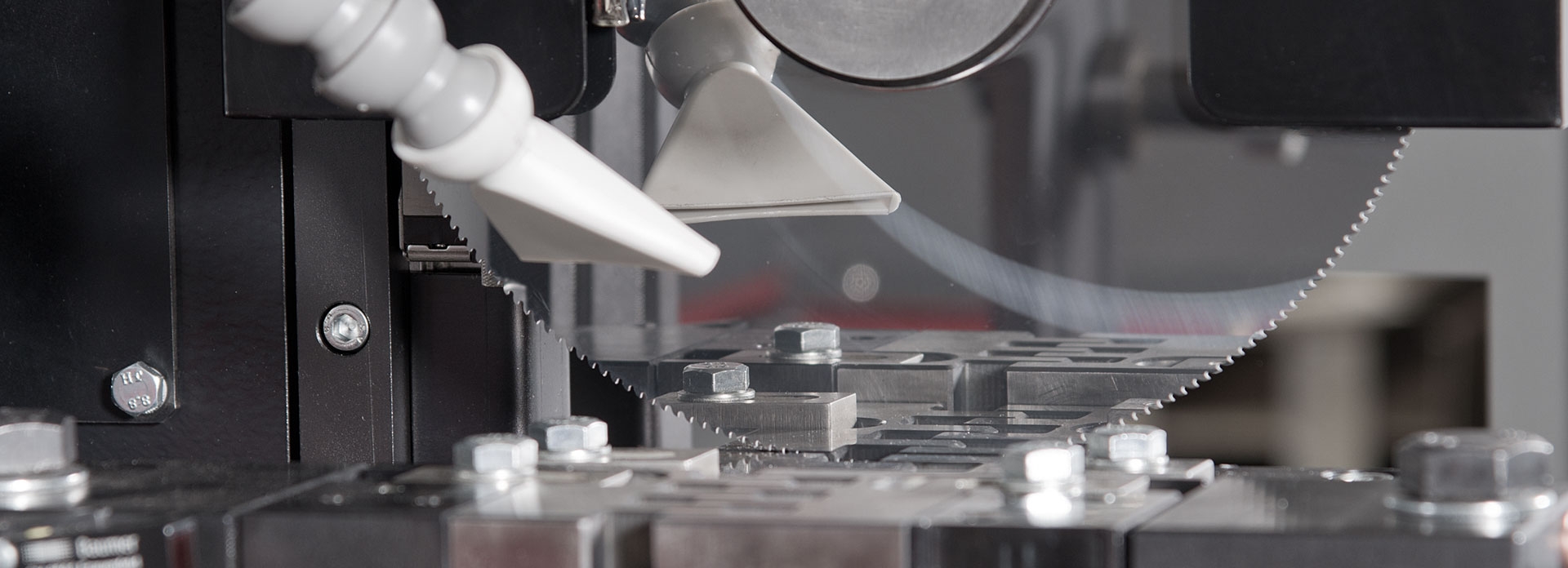

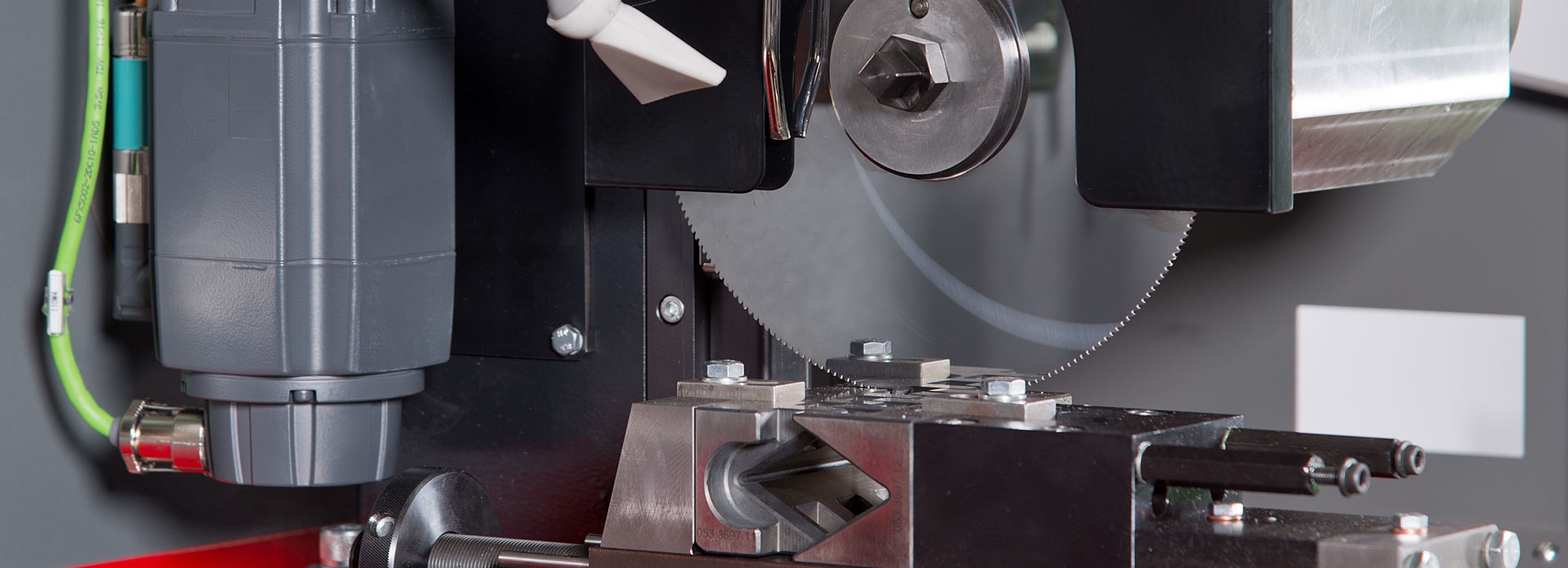

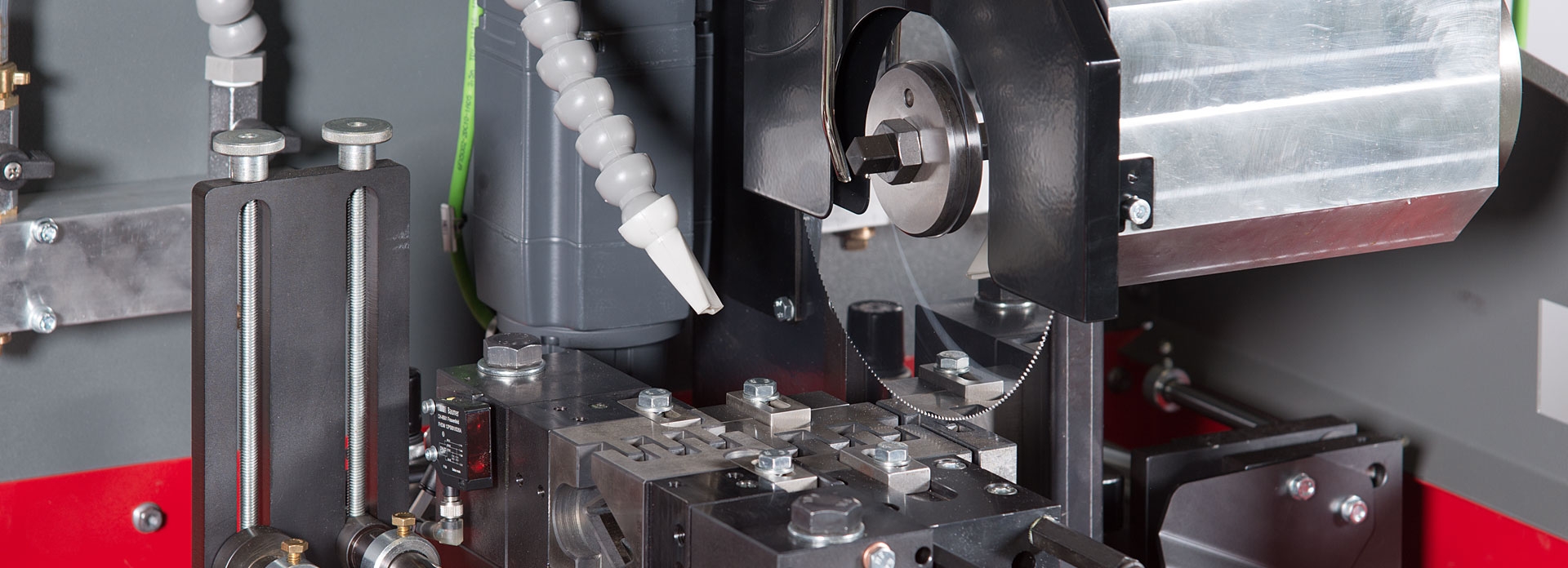

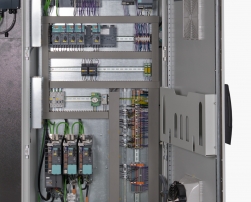

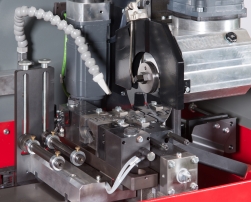

RKA 91, 92 and 94 precision circular saws from Rohbimax, with their precisely-matched jaws, are also suitable for sawing rods with complex external geometries using multiple clamps. Prismatic clamps are used for sawing tubes in bundles, so that the machine achieves high performance, low-burr cuts, and precise lengths down to a precision of ± 0,02 mm. The RKA precision circular saw is controlled using a Siemens S7-1512SP F PLC operating panel. You easily and intuitively define the programming and operation of the system.

| Model | Direct stroke | Material stroke drive |

|---|---|---|

| RKA 91 | 150mm | Pneumatic with cylinder |

| RKA 92 | 600mm | Ball caster spindle, AC servomotor |

| RKA 94 | 1200mm | Ball bearing spindle, AC servomotor |

RKA precision circular saw technical specifications

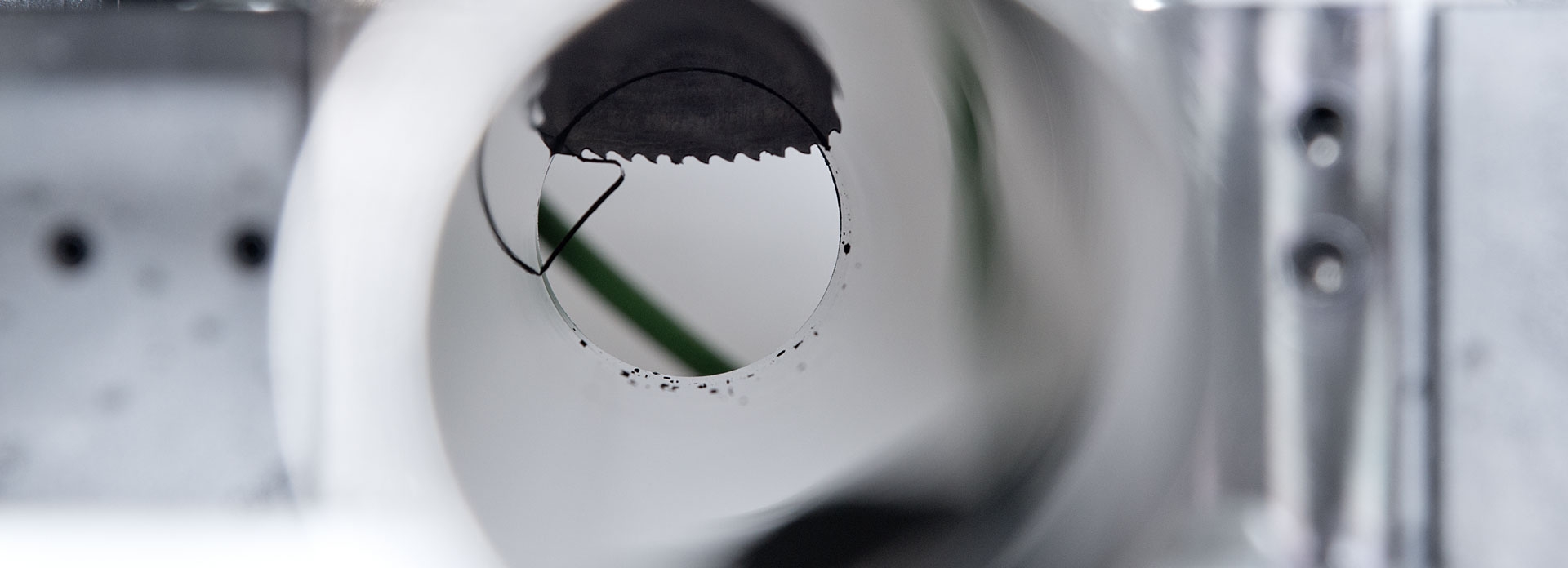

The circular sawblade of our precision circular saw is driven by a step-less, controllable servomotor. We use a three-speed gear spindle for powerful cuts at lower speeds. We use a high speed spindle for processing at higher cutting speeds. This allows customers to work with HSS or solid carbide sawblades. The teach-in process captures the height of the rods to the circular sawblade and can be programmed for five different speeds per saw cut. A pneumohydraulic drive with a proportional valve pushes the saw head and linear guides, which increases precision. The path measuring system is integrated in the guide. The material feeder is driven by an AC servomotor and a ball caster spindle. Positioning is achieved with precise linear guides. The direct stroke length is 600 mm. The sawing head guides are lubricated by pneumatic central lubrication. The sawblade is either cooled and lubricated by flow cooling or a minimal volume lubrication system.

Extensive accessories for RKA precision circular saws

When purchasing Rohbimax automated sawing machines, you can purchase accessories to automate the sawing process. This includes, for example, roller tracks for manual material feed; horizontal or vertical loading magazines for automatic material feeds; removing or handling devices for efficient and gentle removal and fast additional processing of blanks and shavings vacuuming for a clean production environment and to reduce machine cleaning effort.

RKA models, technical data

| Solid carbide | HSS | |

|---|---|---|

| Round materials | 0,6 – 50 mm | 2,0 – 70 mm |

| Profiles | 60 x 40 mm | 80 x 40 mm |

| Circular sawblade - Ø | 60 – 200 mm | 175 – 250 mm |

| Circular sawblade thickness | 0,4 – 1,2 mm | 1,0 – 2,5 mm |

| Geared spindle RPM | 20 – 108 or 40 – 216 RPM | |

| High speed spindle RPM |

1000 – 3000 RPM |

|

| AC servo spindle RPM | 300 – 3500 RPM | |

| Material stroke |

Pneumatic 500 mm or 1250 mm |

|

Special features of the classic RKA precision circular saw

- RPM set to material characteristics

- Precision linear guides in the saw head stroke

- Hydro-pneumatic saw head stroke with proportional valves or ball caster spindles with AC servomotors.

- Siemens PLC controls with a control panel and easy teach-in program.

- Pneumatic or ball caster spindle with servomotor for material stroke

- Cutting tolerances to ± 0.02 mm

- High cut quality up to burr-free as per DIN 6784

- HSS or solid carbide circular sawblades

- Minimal lubrication system or flow cooling

- Fitted clamping tools

- Automation provides a great deal of autonomy

- Progressive rationalisation options

- Ergonomic, user-friendly machine design

- Short equipping times

- High piece through-put due to bundle cuts

- CE compliant

- Meets the highest safety standards