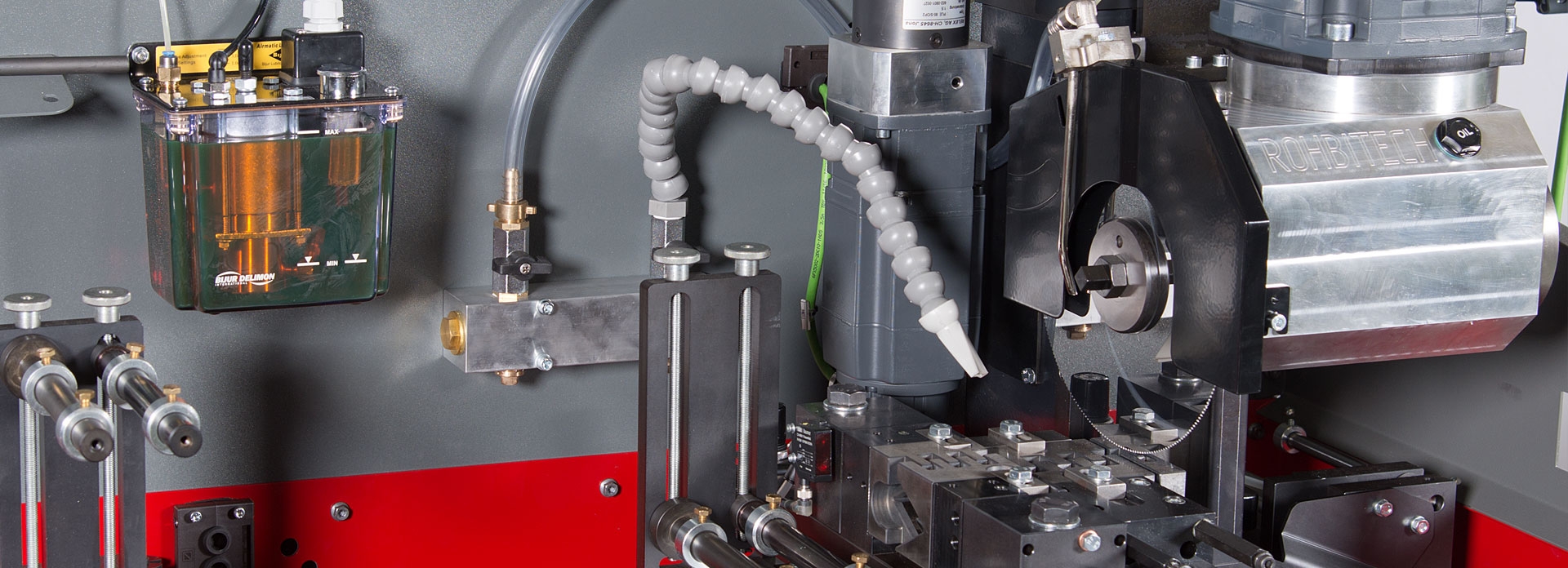

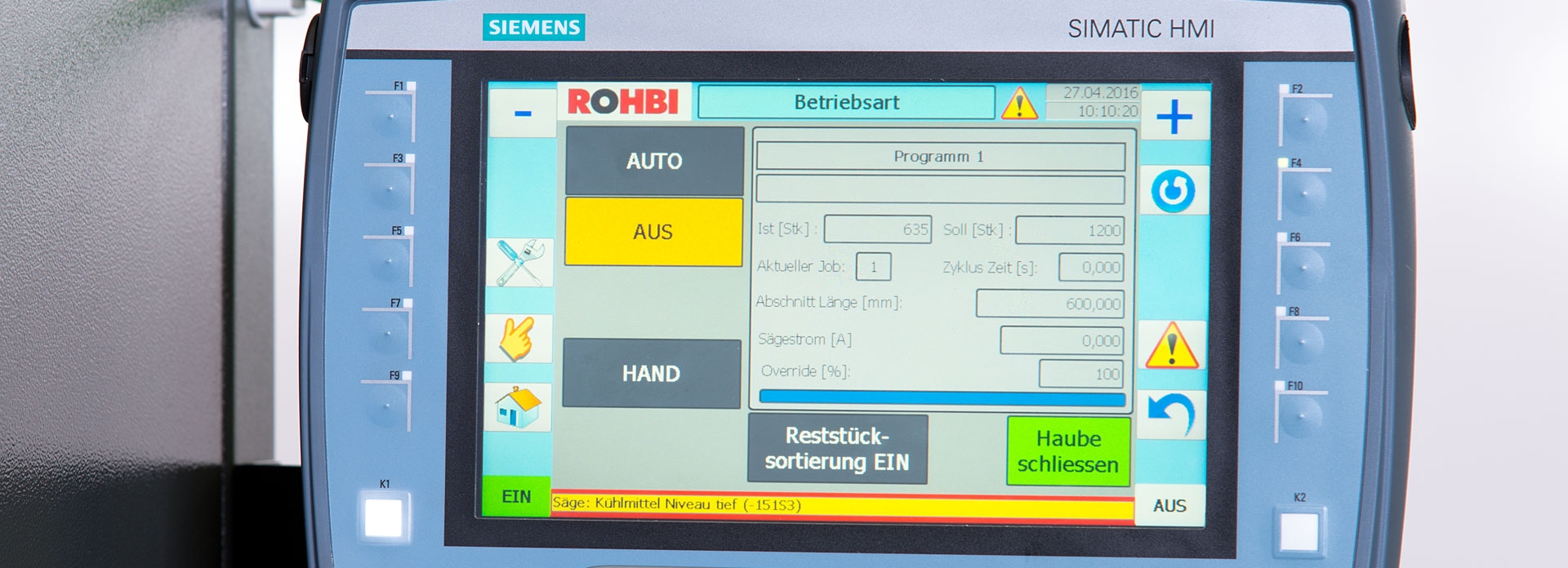

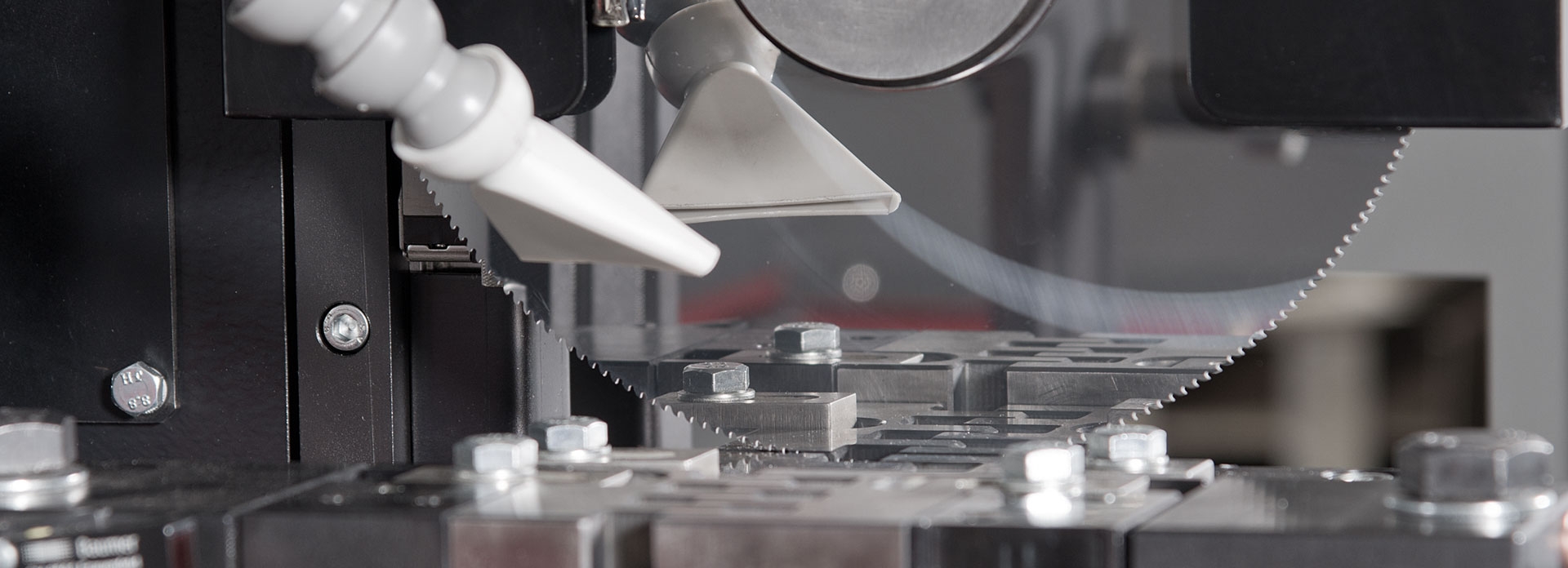

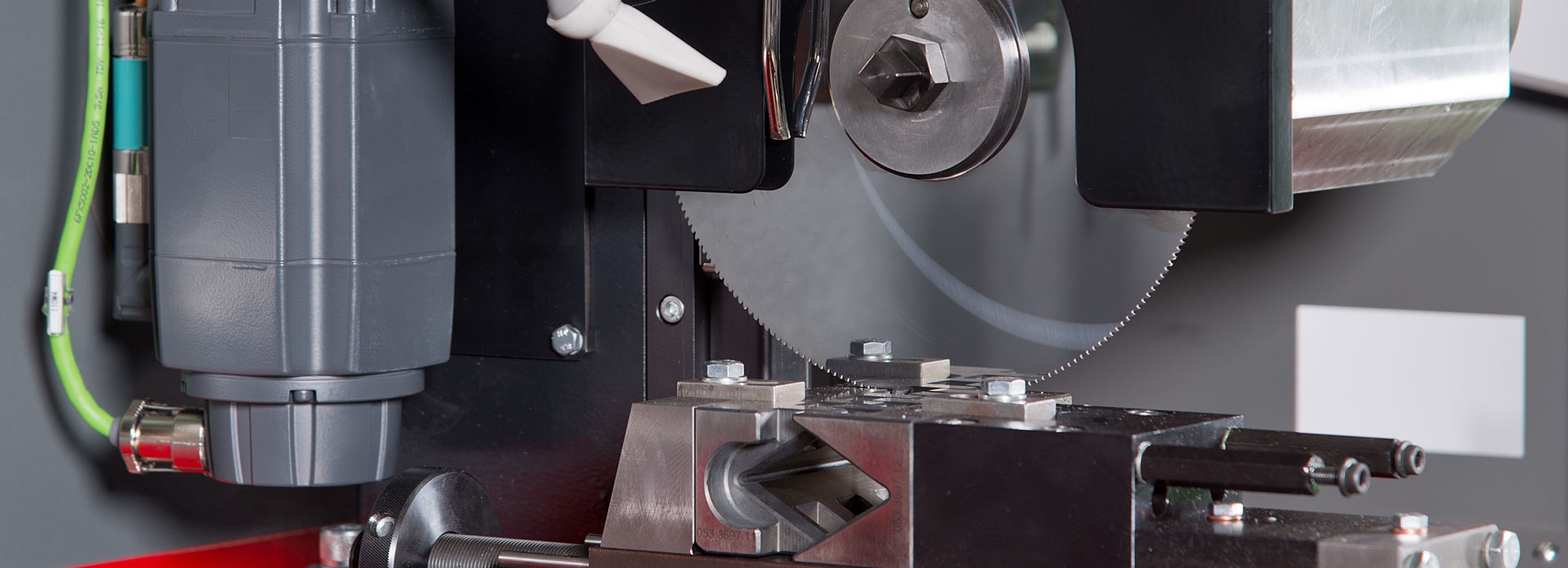

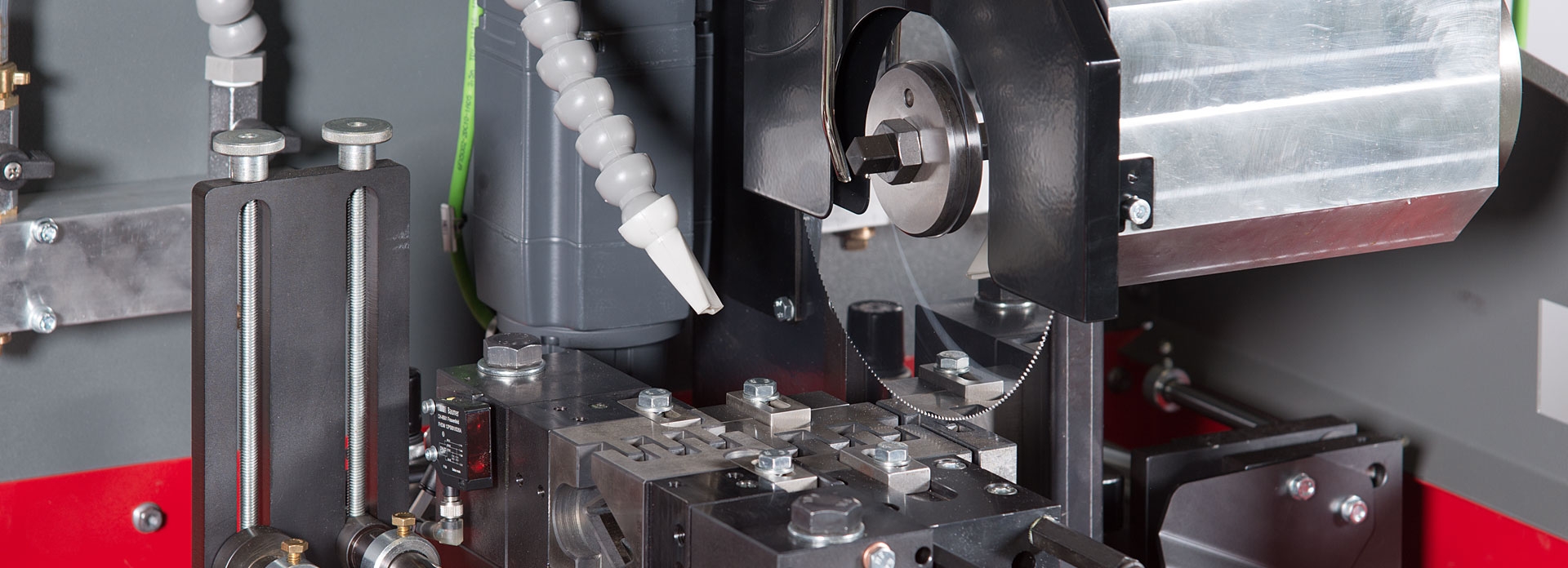

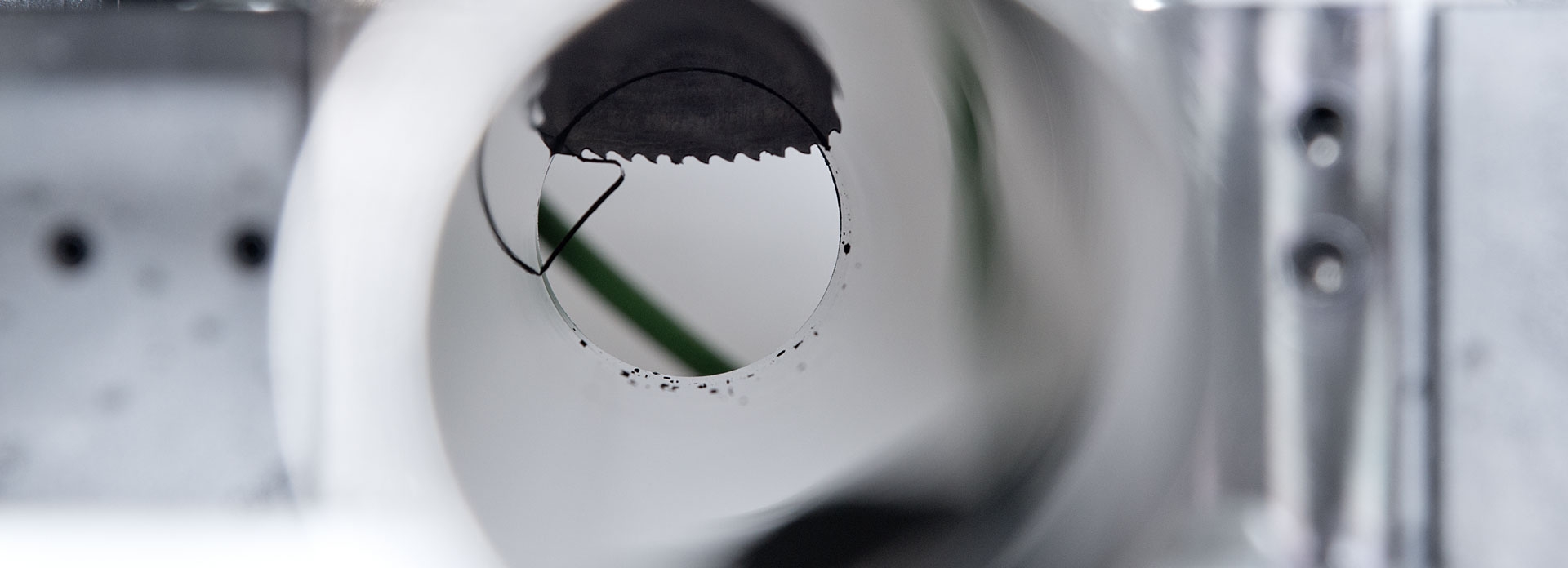

Precision circular saws are a precise interplay within the entire system: Not only the spindle, but also the blade must be produced in a very precise fashion so that the automated precision circular saw separates reliably and precisely together with the feed equipment. The goal is short cycle times with optimal results – from the first to the last cut. Thanks to our high-quality sawblades, you can keep RPMs quite high, cutting every three seconds. The jaws which affix the material to be sawn, and the clamps which push material as needed, are explicitly designed for the materials and optimally fitted to its dimensions. Precision is retained thanks to the automated RKA model stroke, and the machine can operate on its own for several hours.

Precision circular saws for many uses

Precision circular saws are found wherever parts must be cut at the beginning of production. This could be for various metals in the form of solid material, pipes and profiles, and for many other materials. Rohbi Tech AG’s speciality is precision circular saws for all common metals: high- and low-alloy steels, chrome-nickel steel, non-ferrous and precious metals. Areas where they are used include medical devices, construction, vehicle and aircraft construction, machine tools, electrical devices, animal identification and production of jewellery, household and office appliances.

Custom precision circular saws

Let us know where you use precision circular saws, and what materials in what dimensions you’d like to saw. Rohbi Tech precision circular saws can cut pipes with a wall thickness of only 0.1 mm without damage, unlike usual sawing machines. Length tolerance is about 0.02 mm. Rohbi Tech precision circular saws provide low-burr to no-burr results, material-saving processing, outstanding quality and long life. Contact us and set up an appointment for a personal discussion. We’ll find a solution together which fulfils all your automated sawing machine requirements, and with which you will be satisfied for a long time.