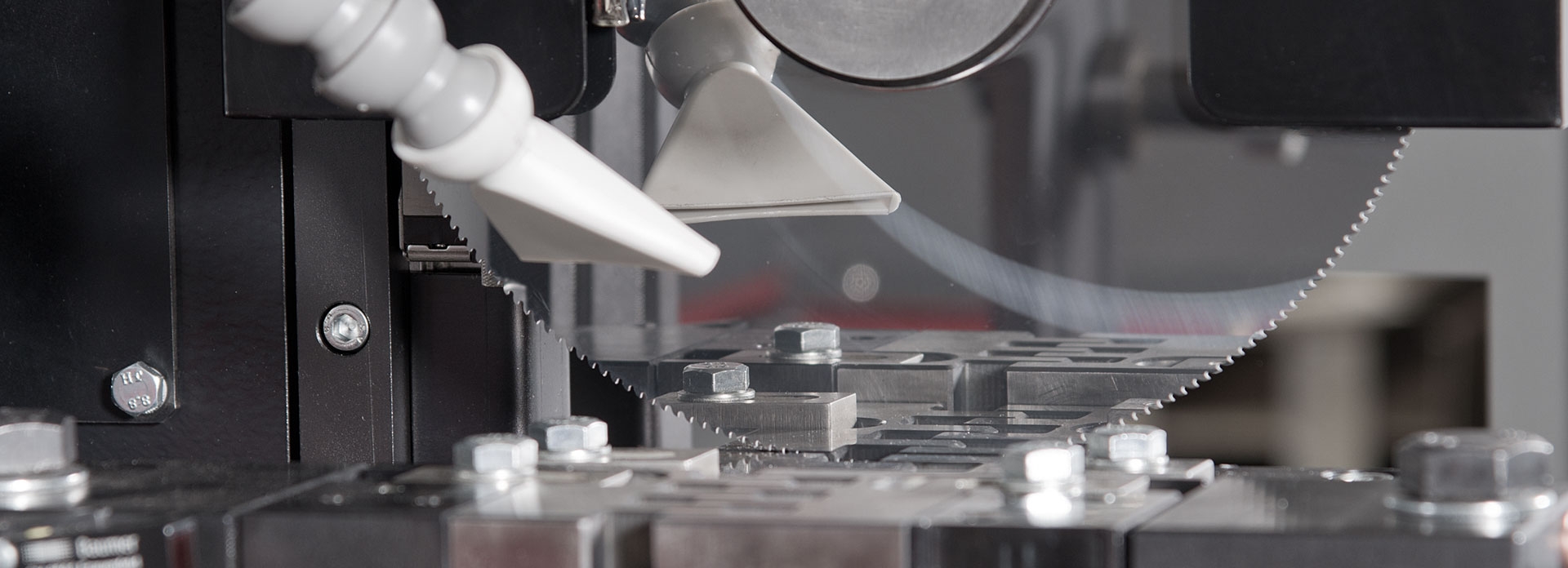

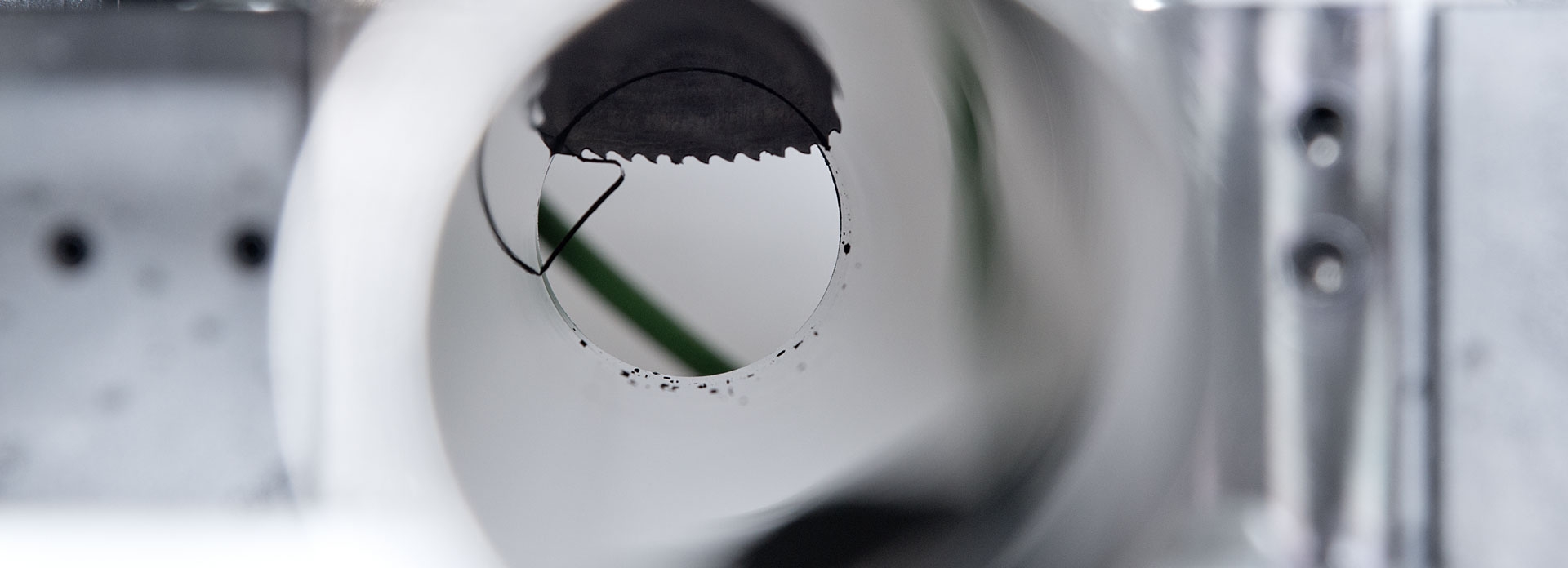

Solid carbide sawblades are available in two different versions: Either the entire blade consists of hard carbide, or it is carbide-tipped, so that the teeth are strengthened by carbide. The solid carbide sawblade has several advantages due to its high resistance. It provides precise results, has a long life, and is therefore more economical to use.

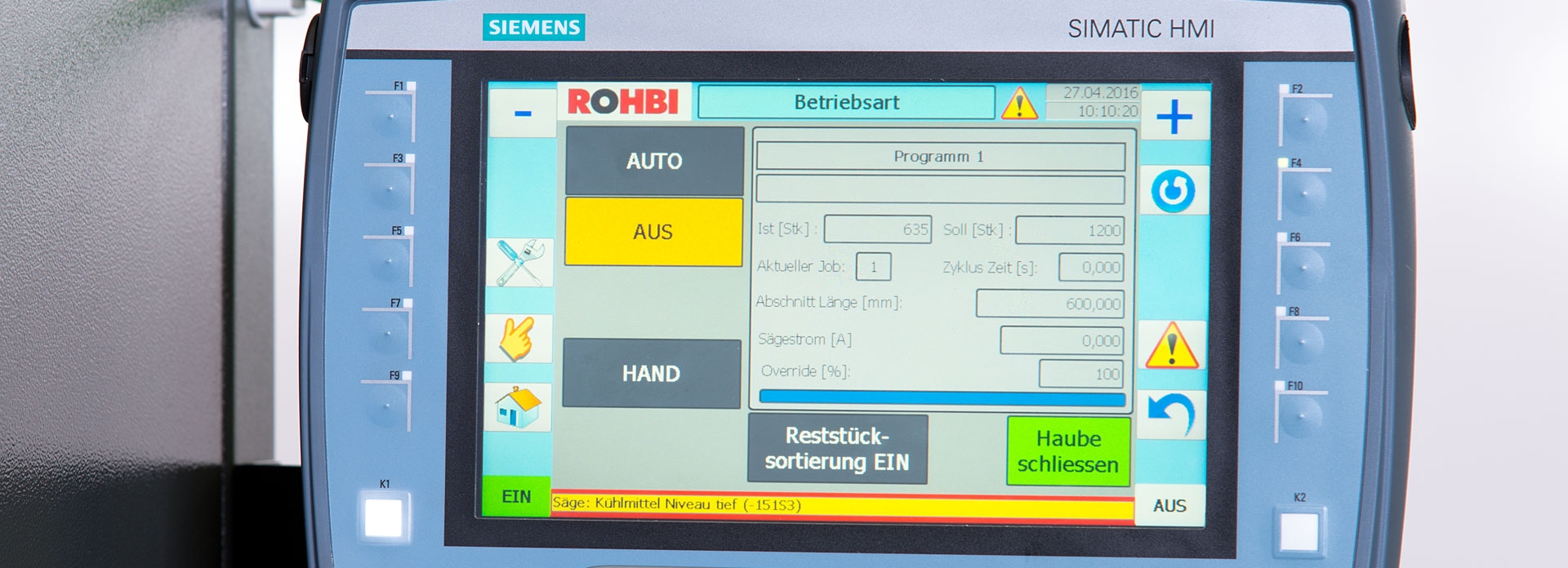

One should only use high-quality sawblades to achieve best results. Only when round and flat runs are high quality and don't turn down can one separate precisely. Rohbimax machines provide length tolerances to about 0.02 mm, low-burr to burr-free processing, and the ability to cut even pipes with very thin walls.

Solid carbide sawblades in various versions from Rohbimax AG

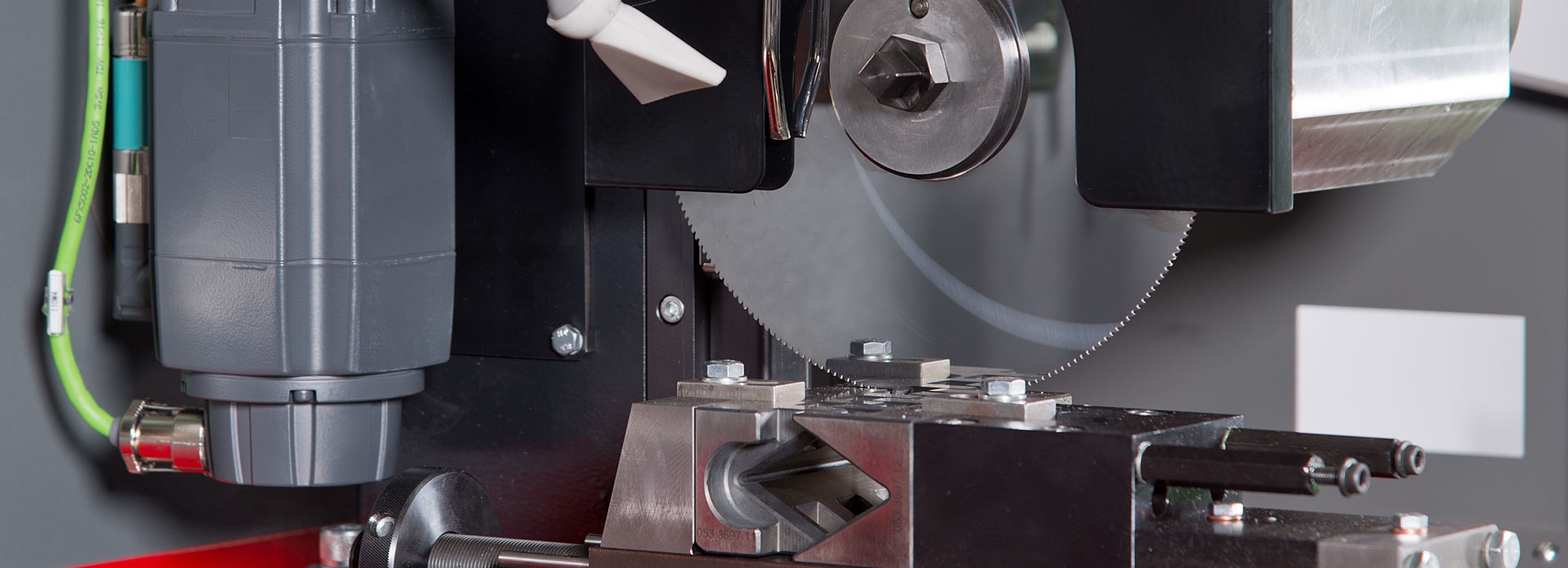

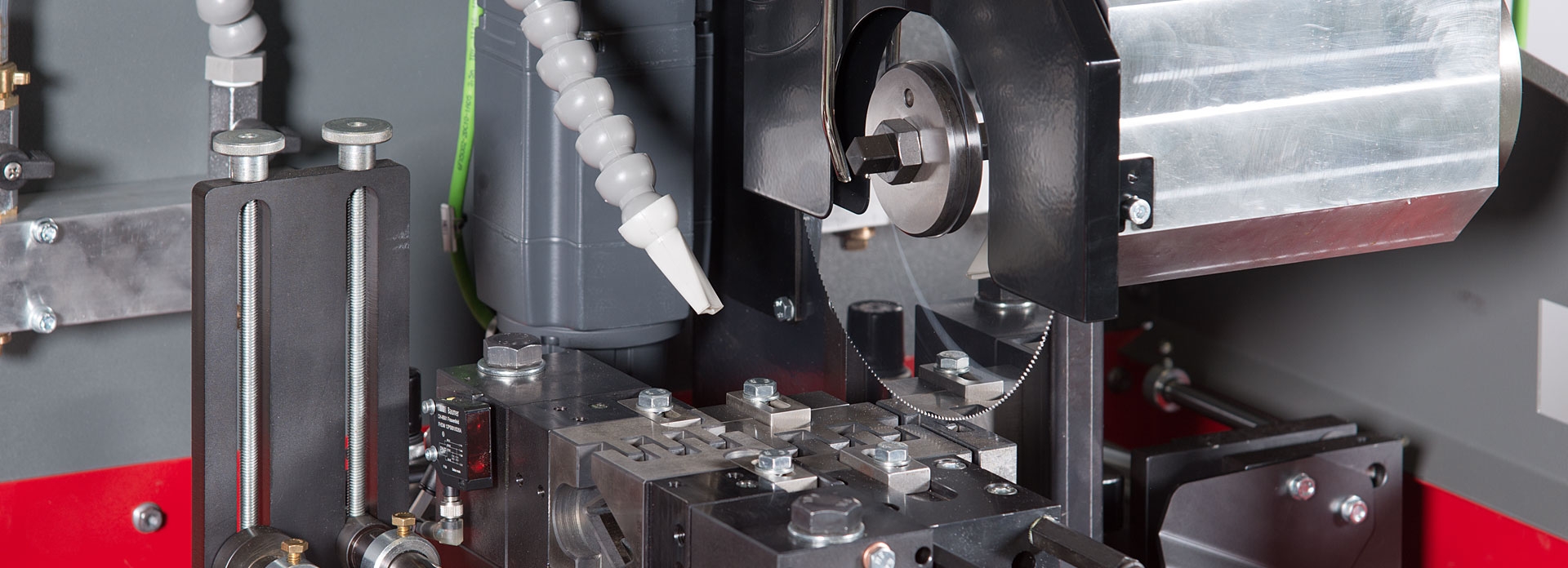

Our plant produces two automated sawing machine series, RKA and KTC. Our RKA models, classic precision saws, use solid carbide and HSS sawblades. KTC machines, which separate non-ferrous metals and steel, use sawblades made of HSS, solid carbide as well as the form with carbide-tipped teeth. We would be happy to consult with you on which versions are suitable for your materials and goals.

Order replacement sawblades from Rohbimax AG

Even if you haven't bought your automated sawing machine from us, we can deliver you our standardised solid carbide sawblades. Thanks to our extensive spare parts warehouse, we can provide you fast delivery times – no need to interrupt your production for a long period of time. In addition, we provide you with maintenance and repair services.

Configure precision circular saws with solid carbide sawblades

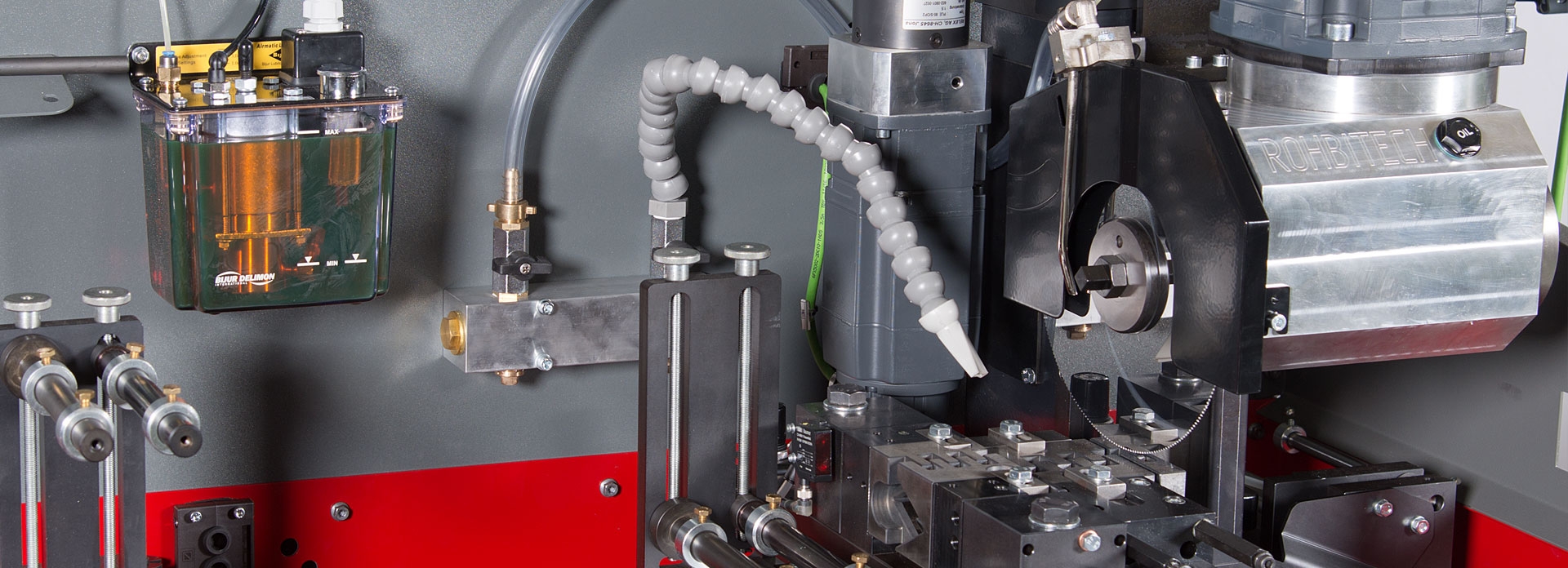

Do you need more than a new sawblade? Is it time for a new system? One of our greatest strengths is designing automated sawing machines which are customised to our customers’ exact needs. Depending upon the starting material, we create solutions with custom jaws and clamps, gears or high-speed spindles, flowing and minimal lubrication, and we consider all wishes for handling, lighting and colour. We offer many peripheral devices, such as bar feeders, so that you can extend your saws as you’d like, to the point that they can operate for several hours on their own. You save time and employee costs while maximising production performance.