Stainless steel cutting is produced from alloy steels with special degrees of purity. These are, for example steels whose contents of sulphur and phosphorus are less than 0.025%. Alloy components frequently used in stainless steels include chrome (for chrome steel), chrome and nickel (for chrome-nickel steel), molybdenum with chrome and nickel (for molybdenum steel), titanium with chrome and nickel (for titanium steel) and niobium. Also, tungsten, vanadium, cobalt and other special steels are used for alloy steels. If the weight fraction of one of the alloying elements is greater than five percent, it is termed a ’high-alloy steel’.

Definition of terms

”Stainless steel” is a catch-all term for a group of more than 160 stainless steels with different components. Its share of harmful elements, such as phosphorus, sulphur, arsenic or tin is particularly low. The blank is made by the experienced Rohbi Tech AG team in Schwarzenbach. These steels are termed ’stainless steel’, as they have a chrome oxide layer which is a thousandth of a mm thick. If a stainless steel cutting causes mechanical damage, it can re-form. Therefore, rust rarely occurs. There are a couple of conditions, however, which must be fulfilled to ensure that your stainless-steel cutting is not affected by rust. The protective layer must not be permanently damaged, through outside rust or chemicals such as hydrochloric acid, for example.

Stainless steel cutting from Rohbi Tech AG

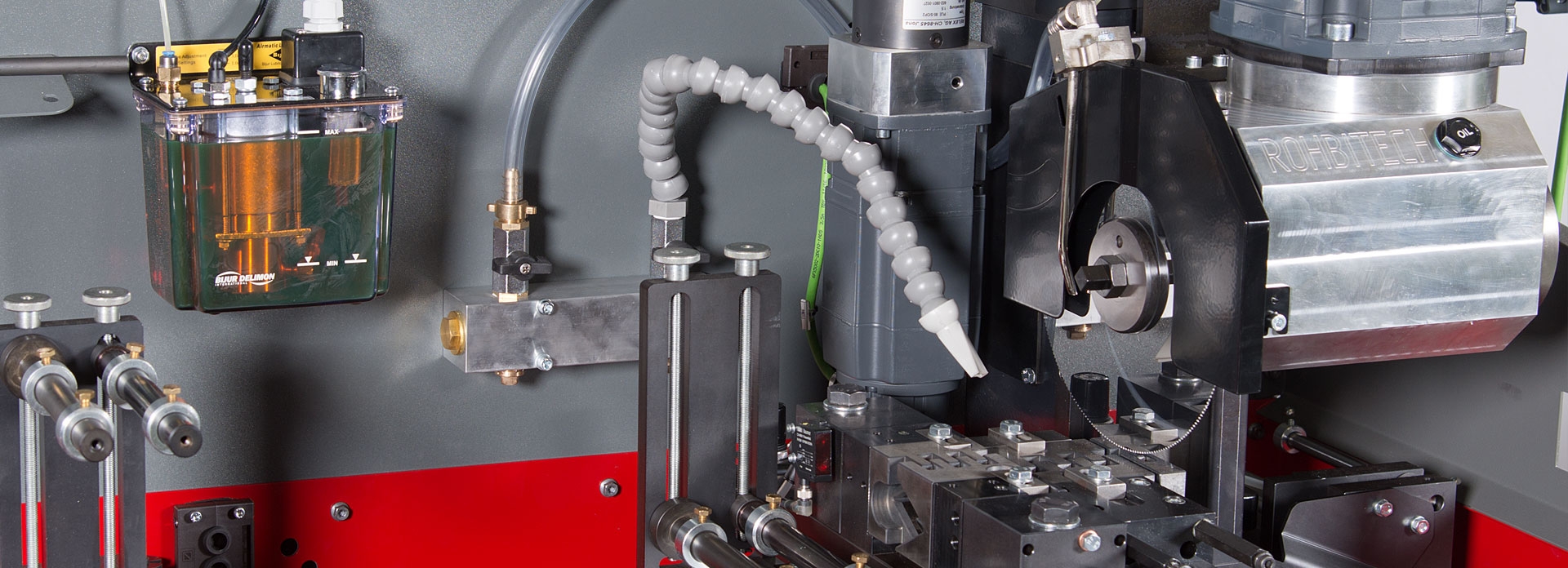

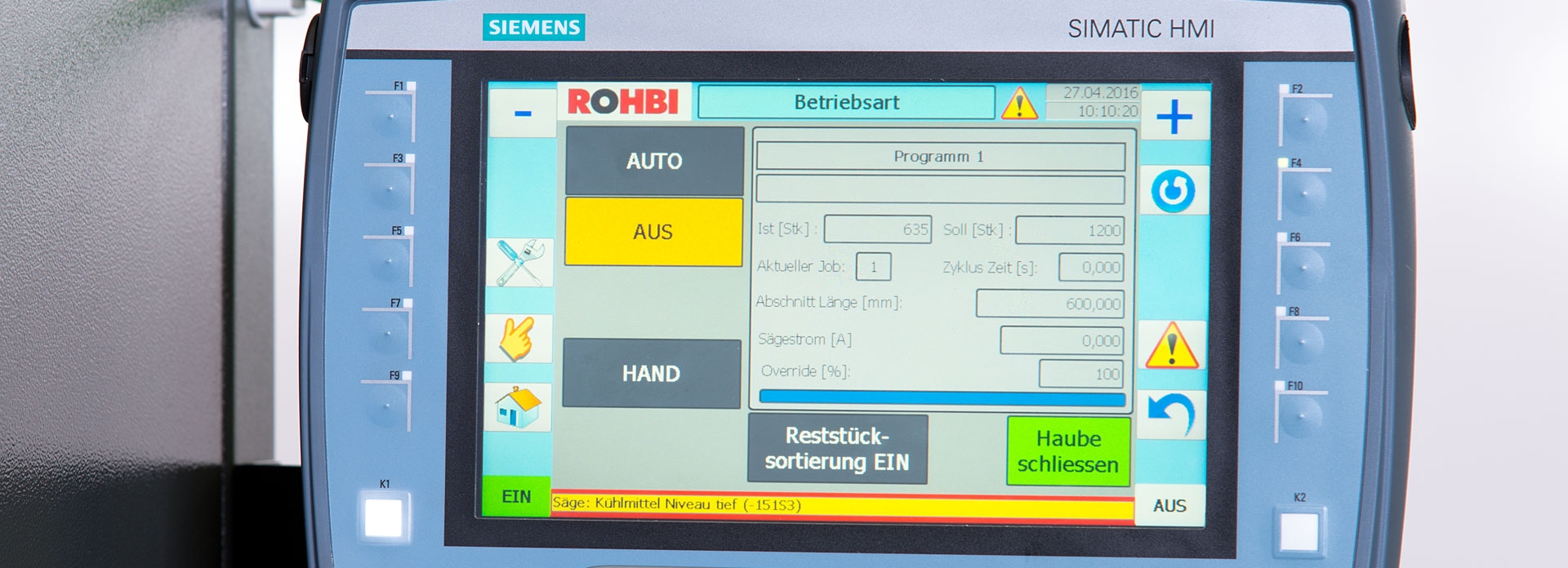

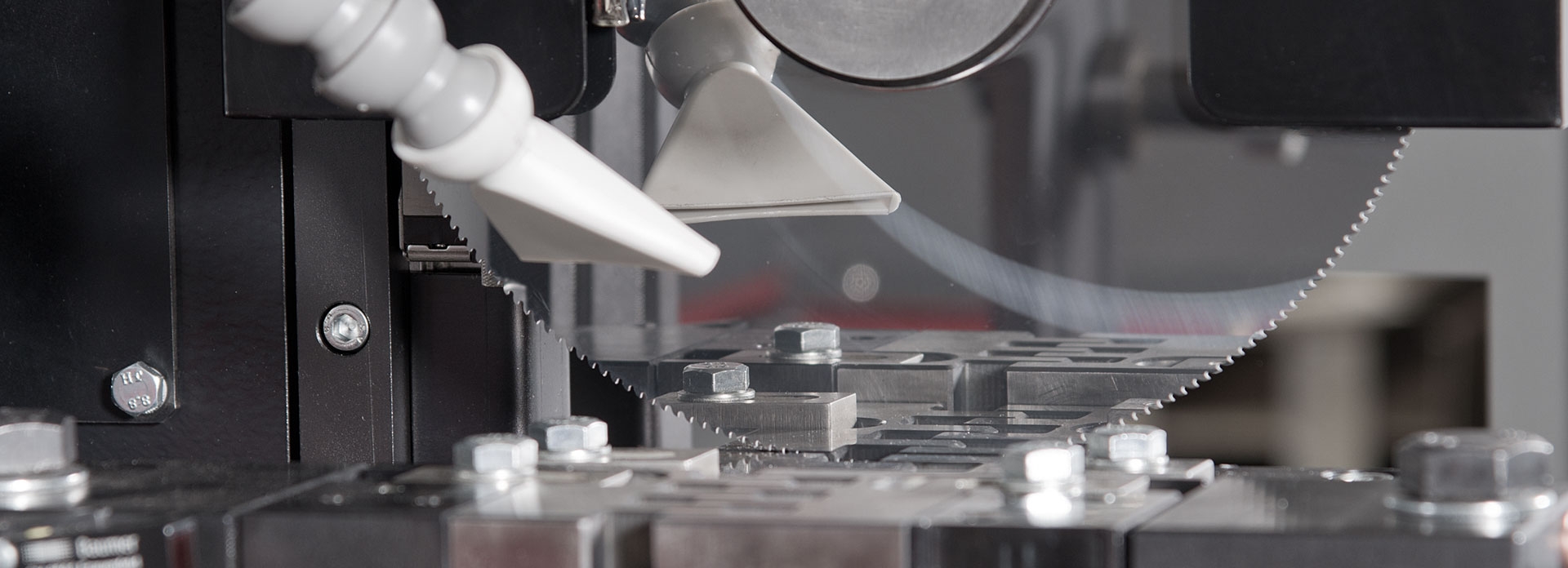

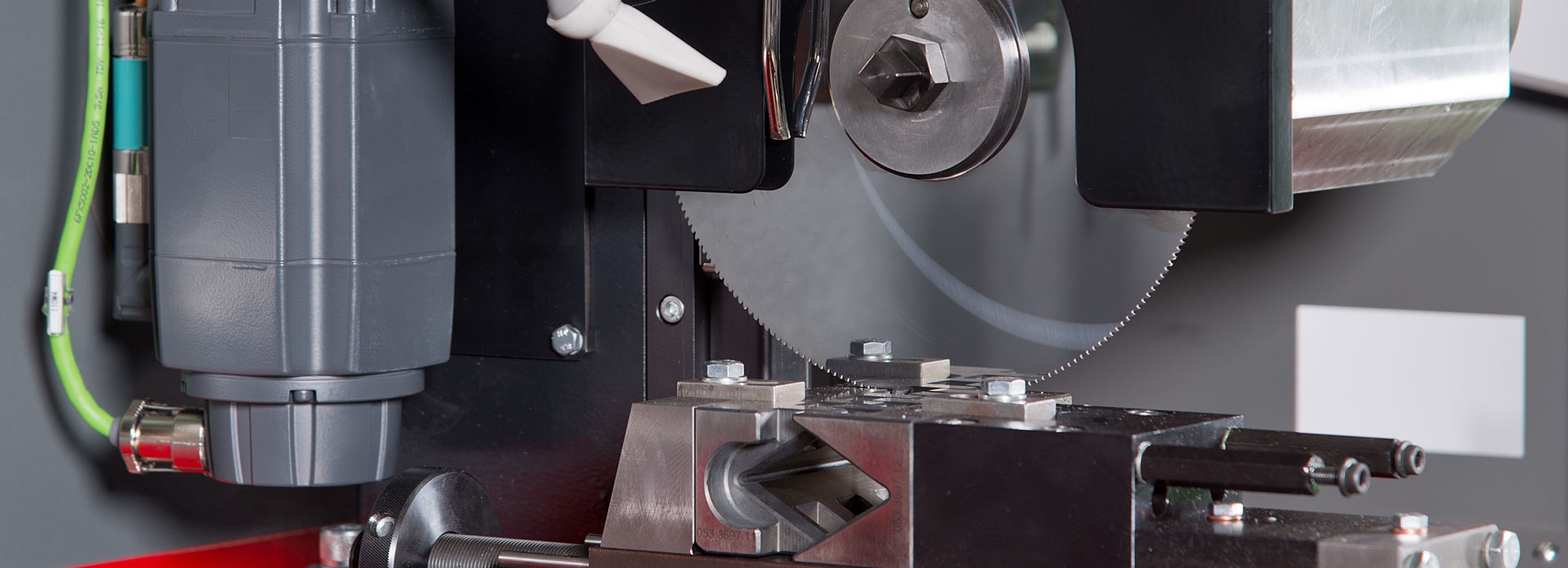

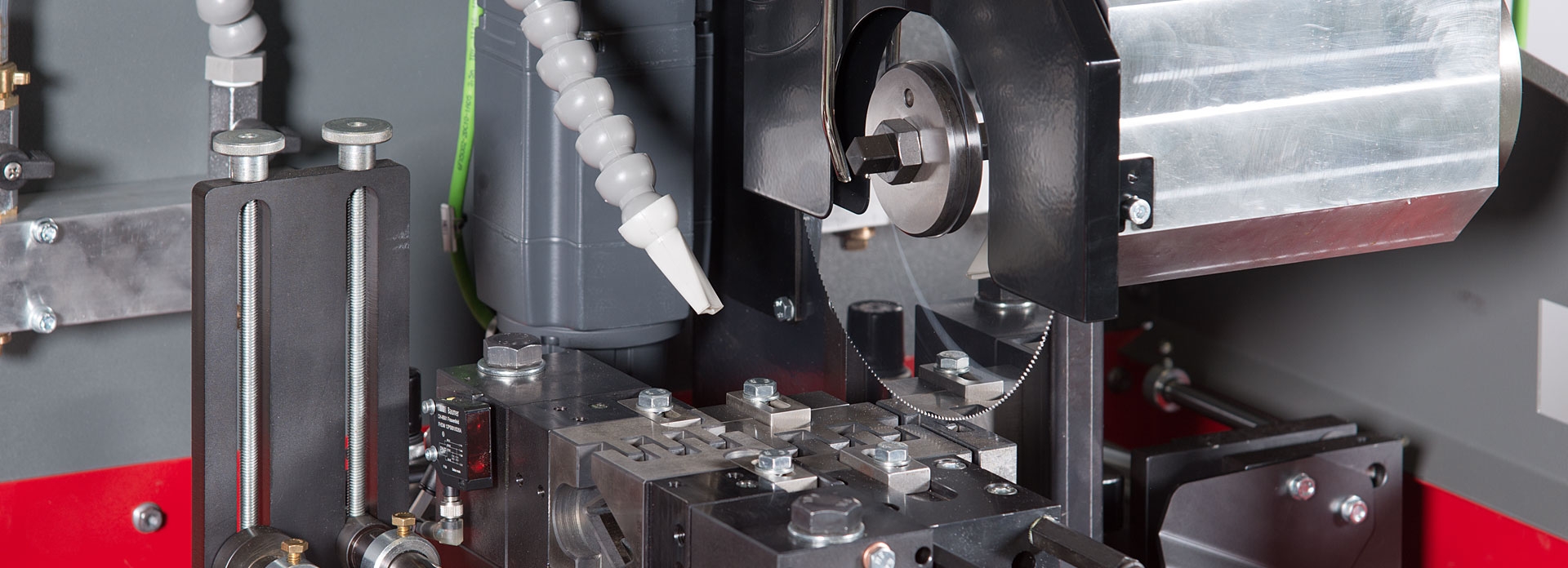

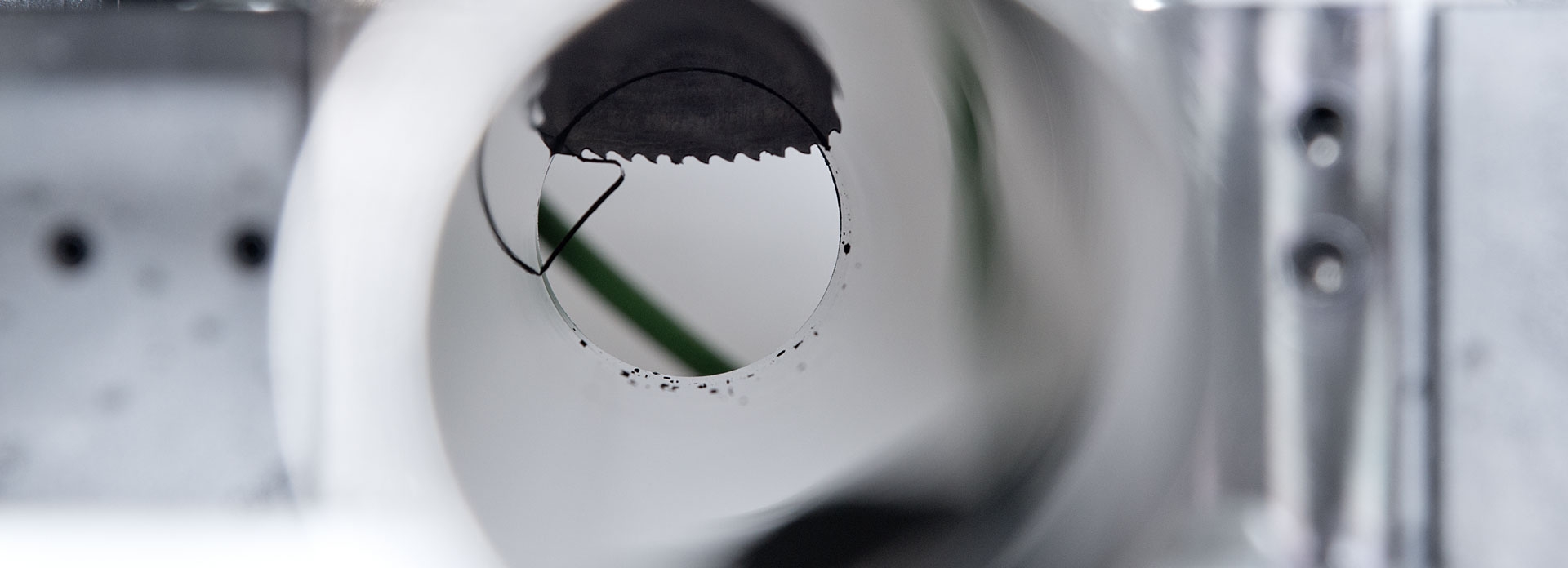

Stainless steel cutting must be precisely manufactured so that it best fulfils its function. Rohbi Tech AG offers you the right automated sawing machines for this. Our RKA and KTC F models are suited to this processing. We specialise in cutting very soft to very tough stainless steel cutting. Using these machines, you can cut close-fitting and precisely, so that nearly no workpiece needs to be post-processed before you use it. Thanks to the high quality of our machines, you can rely on short cycle times which protect the sawblade and save material. We would be happy to provide you with personal advice on your project. Don’t hesitate to contact us.